Core Components of Sandwich Panel Innovation

Material Advancements in Steel Sandwich Panels

The evolution of materials used in sandwich panels, particularly steel, has drastically enhanced their durability and performance. Modern steel sandwich panels now incorporate high-strength steel alloys, which significantly increase durability and resistance to wear and tear. These advancements are crucial in extending the lifespan of buildings, especially in harsher environments. Moreover, coatings and finishes play a pivotal role in protecting these panels against corrosion; statistics show that well-coated steel panels can last up to 40 years or more, depending on the environmental conditions. In addition to steel enhancements, composite materials are being utilized to reduce the weight of panels without compromising structural strength, making them more efficient and easier to handle during construction.

Thermal Efficiency & Insulation Breakthroughs

The latest advancements in insulation technology have made a significant impact on the thermal efficiency of sandwich panels. Modern polyurethane and polystyrene systems have revolutionized how these panels maintain temperature control in structures, contributing to substantial energy savings. Studies suggest that improved thermal performance can lead to a 15-20% reduction in energy consumption, reflecting notable cost savings in heating and cooling expenses. Guidelines such as the ASHRAE standards are pushing for more energy-efficient designs, prompting further innovation in panel insulation. These regulations not only encourage manufacturers to improve product performance but also ensure that consumers benefit from long-term cost savings and more sustainable building solutions.

Structural Integrity for Diverse Climates

Sandwich panels are engineered to endure various climate conditions, tailoring their structural integrity to withstand high winds, extreme temperatures, and other environmental challenges. Case studies highlight the performance of these panels in diverse climates, from cold northern regions to humid southern areas, proving their adaptability and resilience. Experts predict continuous innovations in panel design, potentially incorporating adaptive materials that react dynamically to environmental changes. Such advancements are likely to further bolster structural capabilities, ensuring that sandwich panels remain a top choice for construction projects across different geographical locations.

Versatile Applications Across Industries

Revolutionizing Prefab House Kits with Lightweight Panels

The integration of lightweight sandwich panels into prefab house kits offers numerous advantages, revolutionizing construction practices. These panels reduce both construction time and costs significantly, allowing for faster project completions and budget-friendly housing solutions. According to market data, the interest in prefab homes has surged, indicating a growing acceptance in the real estate market for these efficient and customizable homes. Successful projects, such as eco-friendly residential communities, demonstrate the versatility and efficiency of these kits, showcasing the transformative potential of sandwich panels in simplifying modern home construction.

Modern Chicken Farm Shed Styles Optimized for Ventilation

Sandwich panels play a crucial role in the design of modern chicken farm sheds, particularly in optimizing ventilation and temperature control. These panel systems help maintain an ideal environment for poultry by facilitating continuous airflow and mitigating temperature fluctuations, thus promoting animal welfare. Design case studies highlight how these panels have been effectively used to meet industry standards, ensuring that farms are not only efficient but also humane. By embracing better construction practices, the livestock industry can enhance both productivity and the wellbeing of its animals.

Custom Metal Garages with Modular Assembly

Custom metal garages constructed with modular sandwich panel systems offer an array of features that appeal to diverse customer needs. These systems allow for significant customization options, such as size and function, while also ensuring ease of transport and scalability. The demand for modular storage solutions is on the rise, driven by their flexibility and convenience. As market trends indicate, buyers increasingly prefer structures that can be tailored and expanded to fit their evolving requirements, underscoring the practical benefits of using sandwich panels in modular garage designs.

For a deeper understanding of prefab homes and how lightweight panels revolutionize their construction, consider exploring various [prefab house kits](#) available on the market.

Sustainability in Modern Construction

Recycled Materials in Metal Building Panels

Incorporating recycled materials into metal building panels is pivotal in enhancing sustainability in modern construction. By utilizing recycled content, these panels significantly reduce the carbon footprint associated with manufacturing processes, contributing to environmental preservation. A report from the Recycling Industry highlights that using recycled materials can cut energy consumption by up to 80%, illustrating the profound impact of these initiatives. Furthermore, eco-certifications such as LEED (Leadership in Energy and Environmental Design) and ENERGY STAR are essential in promoting sustainable practices, symbolizing a commitment to eco-friendly building designs. These certifications not only reflect adherence to high environmental standards but also encourage the construction industry to move toward greener solutions.

Energy Conservation Through Smart Design

Smart architectural design with sandwich panels plays a critical role in promoting energy efficiency and sustainability. These panels are engineered to enhance thermal insulation, ensuring that buildings remain energy-efficient throughout the year. Data from industry studies indicate that buildings designed with advanced sandwich panel systems can achieve energy savings of over 30%, illustrating their effectiveness in energy conservation. Looking ahead, the integration of smart technology within building designs is a promising trend. Innovations such as IoT-enabled panels that adapt to temperature changes are set to revolutionize how energy management is handled in construction. These future trends signify a shift towards more intelligent, responsive building environments, underlining the potential of smart designs to conserve energy while enhancing comfort.

Engineering Excellence in Manufacturing

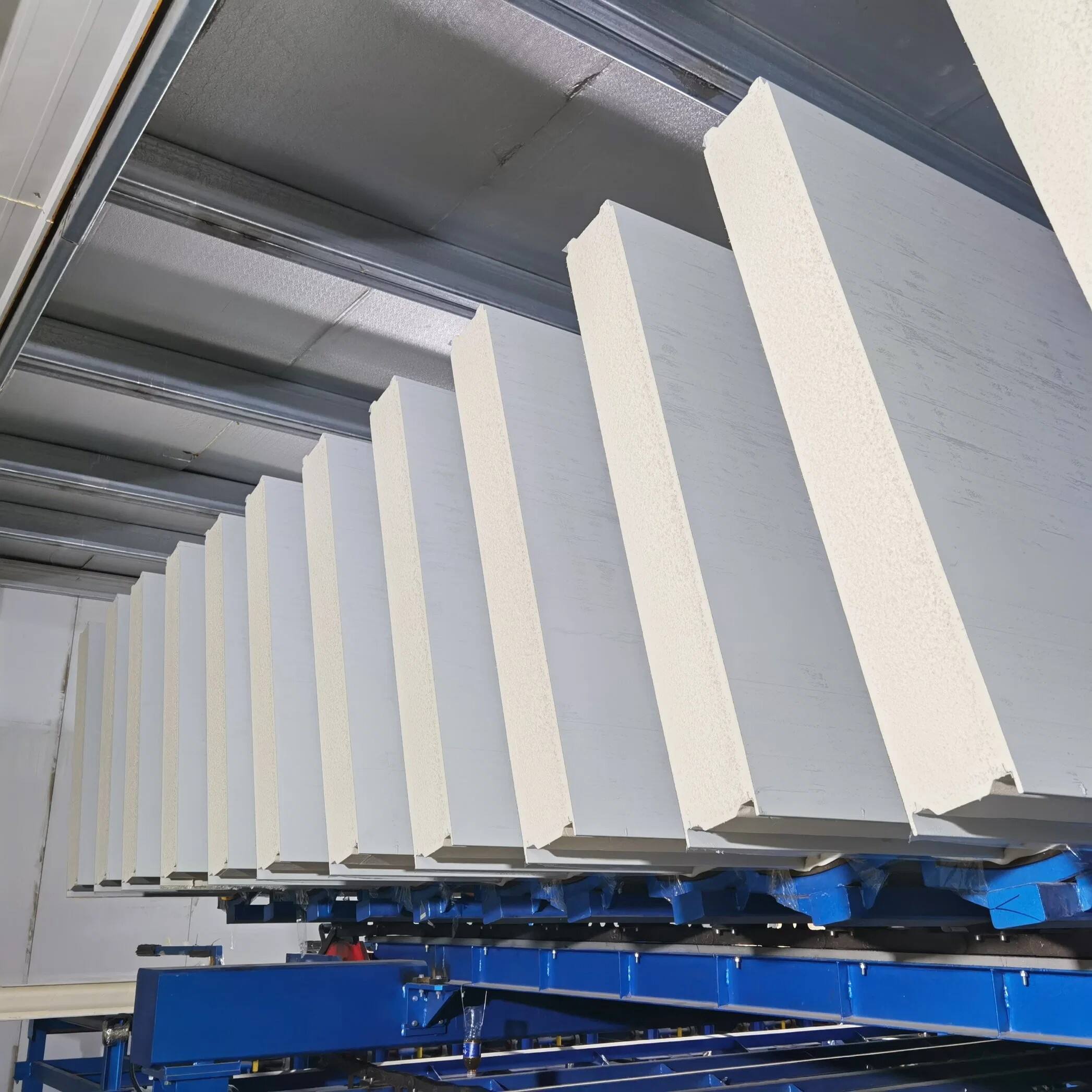

Automated Production Lines for Precision

Automated production lines have transformed the manufacturing landscape, especially in the production of sandwich panels. By integrating cutting-edge robotics and control systems, manufacturers achieve unparalleled precision and efficiency. Automation technologies ensure that every panel meets stringent specifications, reducing human error and waste. Moreover, these systems allow for scalability and flexibility, adapting to varying production demands without compromising on quality.

- Production Efficiency: Automation significantly enhances production efficiency, enabling faster turnaround times and reducing operational costs. This is achieved through optimized assembly processes, real-time monitoring, and adaptive machinery.

- Consistency: Automated lines offer improved consistency, ensuring that each product is identical and adheres to quality standards. This minimizes defects and ensures uniform performance across all panels.

- Future Innovations: Looking forward, advancements such as AI-driven predictive maintenance and IoT-enabled smart factories are set to drive even higher standards in manufacturing precision. These technologies promise to not only maintain but also incrementally improve production efficacy over time.

Quality Control in Steel Panel Fabrication

Quality control is the backbone of superior steel panel fabrication, ensuring that all products meet established standards. Rigorous testing and inspection processes are embedded within the manufacturing lifecycle to catch defects early. These measures include automated non-destructive testing techniques, which verify the integrity of each panel without harming its structure. Furthermore, statistical process control is employed to monitor production variables continuously and maintain quality consistency.

- Defect Rates and Improvements: Implementation of comprehensive quality control measures results in lower defect rates, enhancing product reliability. Data-driven analytics have shown substantial improvements in defect identification and correction over traditional methods.

- Certifications and Accreditations: High standards of quality assurance are maintained through relevant certifications and accreditations. This includes ISO certifications, which assure clients of the robustness of processes and the reliability of panels.

Through precision engineering and stringent quality control protocols, the manufacturing sector of sandwich panels is poised for continuous innovation and excellence, meeting the growing demands for high-quality and sustainable building solutions.