In manufacturing and construction industries, sandwich panels are becoming more popular for various applications. This post attempts to explain why innovations in manufacturing processes for sandwich panels receive so much attention. It looks into industry concerns, processes employed and highlights trends on sandwich panels.

These panels have a unique ratio of strength. They also offer exceptional thermal insulation. Also, other modern methods such as robotics and automated systems, precision cutting, and advanced bonding are used in the production of these panels. While the quality of the panels is improved, costs are lowered, and production is streamlined to reduce waste.

The most crucial step in the making of the panels is their assembly with Sandwich Panel Automatic Assembly Lines. Due to robotized assembly, units produced are homogenous to the last detail. Repetitive operations like cutting, layering and bonding sandwiches to make panels are now done by Robots. The firm can reduce human error, accelerate production, and enhance their profit due to the currently saturated market.

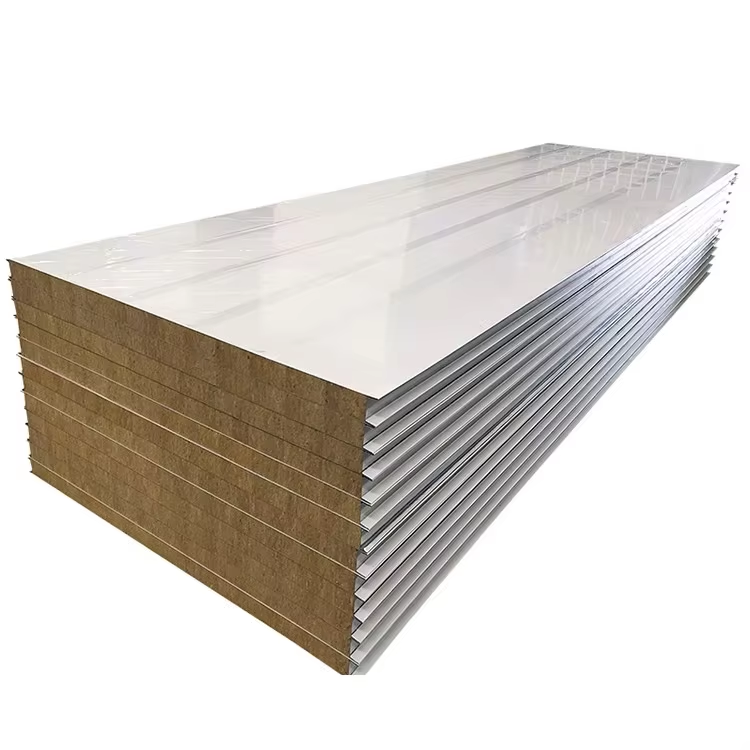

Like in any manufacturing operation, the selection of the materials in the construction of the sandwich panel needs careful consideration. Steel or Aluminum are commonly employed metals for the outer parts while the core can be Polyurethane, Polystyrene or even Mineral Wool. In modern manufacturing, materials that require testing and satisfying performance benchmarks like thermal insulation, fire resistance, and support structure are crucial for modern controls.

The development of new bonding techniques has changed the traditional methods used in the creation of sandwich panels. Enhancements in technologies like laser bonding or ultrasonic welding are applied to situations such as adhesive bonding. The layers get bonded more stably, and more tightly, which increases reliability and utility for the consumer in diversified conditions.

There is a shift in the trends of the sandwich panel industry as consumers integrate energy saving features and sustainability into building materials. Incorporation of recycled materials into the core components has been adopted by manufacturers. This change meets the environmentally sustainable objective while fulfilling the market need.

In summary, the automation of operations and adoption of new technologies in construction and manufacturing processes facilitates the use of precision engineering techniques in the manufacture of sandwich panels. It is common for manufacturers to apply sophisticated systems, high-quality materials, and advanced bonding methods with the aim of improved performance, sustainability, and efficiency of the products. Our expectations are continued innovations in the industry and the future of sandwich panel manufacturing.