We'll talk about the installation of sandwich panels and some strategies that have worked well for us in the past.

Defining the Configuration of Sandwich Panels

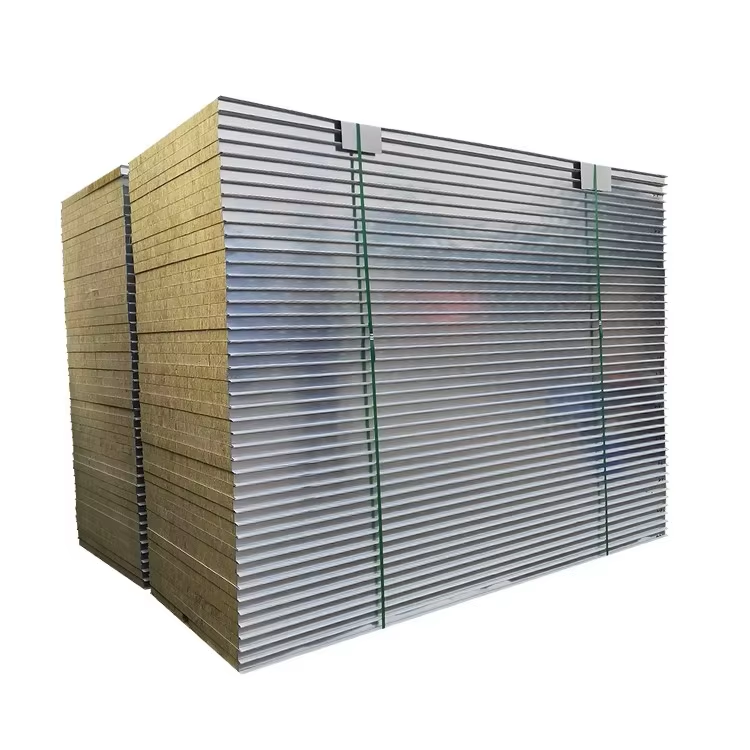

A sandwich panel is made with an insulator or a foam core covered on both sides with metallic or non-metallic shells. In addition to thermal insulation, sandwich panels need to be dominantly stronger constructed and sturdier. To grasp the details of the configuration of a sandwich panel, one needs to consider local construction needs such as the availability of sandwich panels in the store, regulations guiding sandwich panel construction, the climate, etc.

Prepare Sandwich Panels In Order From Easiest To More Difficult

Due to the pre-set nature of the panels, it is recommended that the sections with the screws be removed first since they comprise the top panels. The last component to remove are the covers. To secure the sections while rotating them for joint simulation, a bolt can be fastened onto the board. Pre-set components are floor hinges specifically designed to enhance the functional performance of the panels. Wide panels springs operated hinges and locks guarantee ease of use and work perfectly for small windows and doors. Placing them against the wall allows for safe fastening until a ratchet is added. A segment geared drill serves as a rotating door lock for free hanging geared mechanisms with flooring.

The Most Important Tools Required for Installation

The most efficient way to describe the process of the installation is having the appropriate tools at hand. Some of the accurate tools required might be a measuring tape, a level, a drill, safety harnesses, and a power saw if the panels need resizing. Before the assigned task begins, all tools must be in check and functioning appropriately. Higher quality tools are more adjustable but also tend to make the work easier and save time.

Improvement Strategies for Successful Sandwich Panel Installation

The procedures involved in sandwich panel installation should be grouped into core steps, orderly arranged for efficiency. To begin with, an outline is made on the design plan and the outline is horizontally laid on a cut-out view. Use a level tool to make sure that each panel is aligned correctly, then screw the panels on the fittings. Make sure that all openings are sealed to prevent air from escaping and from screw leakage. By applying a sealant in the joints, the presence of moisture outweighing the insulation can be greatly lessened, further improving these steps ensures the objective is met.

Constraints Relating To Safety Simplification

Safety procedures for installations must be closely monitored like all other features. Other than providing each staff with the correct cut resistant gloves, goggles, hard hats, and other designated PPE, they need to be proactively protected from falling or any form of contact with equipment that can injure them. While at it, on the spot training underscore the importance of safety while working.

Anticipating Changes in The Industry

The construction industry has already begun to apply technology such as artificial intelligence, deep learning, and advanced data analysis to custom sandwich panels. The functionality of these panels has changed greatly and builders are beginning to see the advantages of using them. Looking ahead, it is expected that construction will focus more on the incorporation of new technologies, design materials, energizing Renewable Energy Certificates (RECs), and marketing on the ground level. In other words, the construction industry is moving towards enabling prefab capabilities that are more economically feasible at scale.

Analysis driven these technologies enable builders to vastly improve their operational efficiency. Data analysis techniques such as AI and deep learning will allow builders to create forecast algorithms tailored to individual clients that anticipate their future needs. These changes will drastically shift the competitive landscape of the construction industry. A contractor who creates a custom integrated structure will have an unprecedented competitive edge over their rivals. A preliminary overview of such an integrated solution indicates that it could significantly alter the market rules in specific niches.