In the cold storage sector, the right sandwich panel selection is important for effective temperature control and energy consumption. It is important to look at the different types of sandwich panels for cold storage, their advantages, and the various selection criteria that are practical for your needs.

Introduction to Sandwich Panels

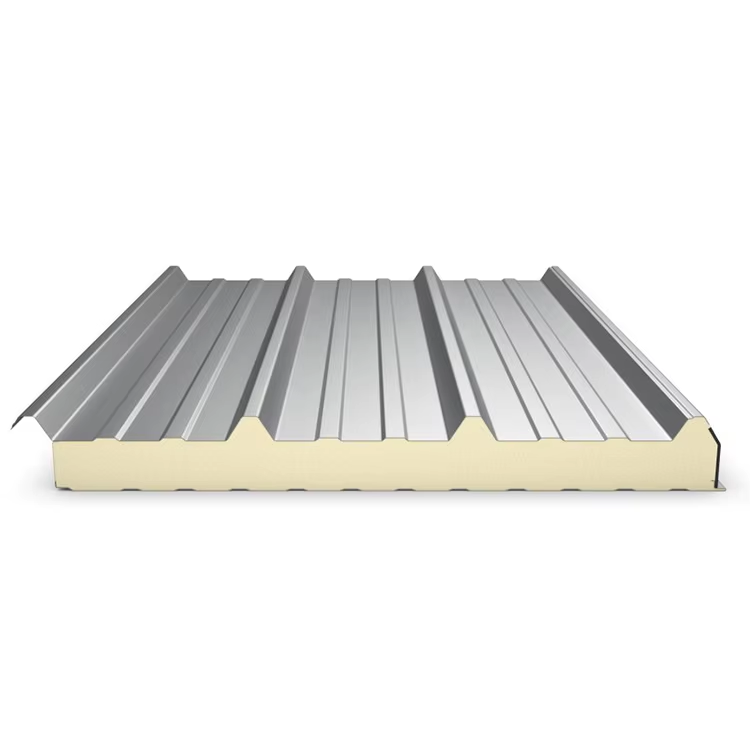

Sandwich panels are made of two external layers and an internal layer of insulation. Their use is widespread in the construction of cold storage units because of their remarkable insulation efficiency. The choice of outer layers and core materials impacts the panel’s cold performance. Common materials include polyurethane, polystyrene, and mineral wool, each having their own benefits.

Important Features to Keep in Mind

A set of features must be kept in mind in regard to sandwich panels used for cold storage. Thermal conductivity is of primary importance and lower value is preferable. The panels’ overall strength, insulation against water ingress, and fire ratings are also critical for safety and useful life of the panels. Furthermore, activity for the cold storage facility and efficiency of workflow also depend on the maintenance and installation of the facility.

Different Sandwich Panels for Cold Storage Facilities

- Polyurethane Panels: Polyurethane panels are best suited for cold storages that require stringent temperature control. They have high R-values and are lightweight which makes them easy to handle. Also, they provide high insulation.

- Polystyrene Panels: They are an economical choice for slightly less demanding cold storage applications. Although they lack high temperature extremes resistance and insulation capabilities, they do offer some resistance to moisture.

- Mineral Wool Panels: They provide excellent thermal insulation and are also fire resistant. They are suitable for cold storage facilities which require high fire safety standards.

Cost and an Energy Efficiency Overview

International standards suggest that energy efficiency for cold storage should always be prioritized because it directly impacts the operational costs. Temperature difference heating Sandwich panels with high insulation values minimizes the energy used to control the temperature in the facility. It is true that materials with higher insulation value, for example, polyurethane, have higher upfront costs, but in the end the savings in the energy bills makes it a worthy investment.

Trends And Innovations Thawing the Cold Storage Industry

The cold storage industry is transitioning toward the use of sustainable building materials, zeroing in on eco-friendly insulation alternatives. Withdrawal of older less efficient products is cheese, ever improving winding insulation materials, the manufacturing of insulation plates is making sandwich panel technology better in efficiency and cleanliness. Accessories that have specialized functions are bound to become more readily available.

In summary, the use of sandwich panels in cold storage construction involves more than simply grabbing the cheapest and the most efficient panels. Their functions, prices, and terms of acceptance must fall under the required level. The more operators of construction of cold storage and refrigerating appliances know the possibilities of their components and the more they are aware of the use of economical parts, the more the costs will drop.