Thermal Insulation Performance of Rock Wool Sandwich Panels in Metal Building Envelopes

U-value Optimization and Condensation Control in Steel-Framed Cladding

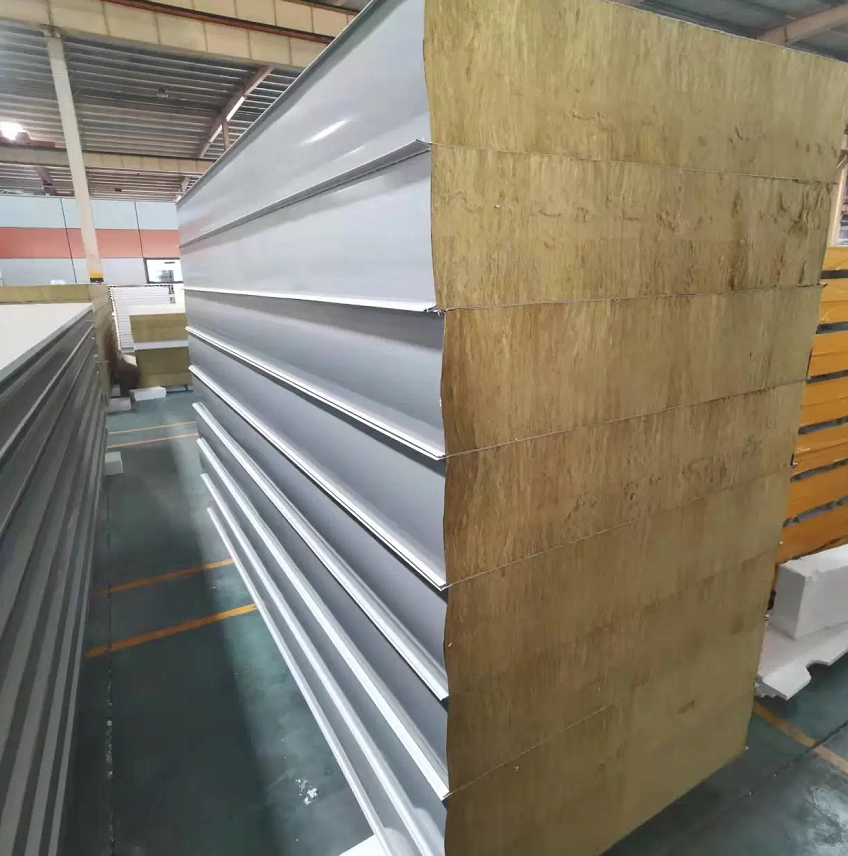

Rock wool sandwich panels offer great thermal efficiency for metal buildings, with typical U-values ranging from 0.20 to 0.30 W/m²·K. This means they cut down on heat transfer through steel frames pretty effectively. The mineral core inside stays consistent even when temperatures swing wildly, and it stops those annoying thermal bridges where different materials connect. What makes these panels really work well is their ability to let moisture pass through rather than trap it. This prevents condensation buildup between layers that would otherwise lead to rust problems in metal components. When indoor temperatures stay more stable, building owners see real savings too. Studies show HVAC systems need about 25% less energy when using properly insulated panels versus going without insulation or settling for inferior options. Plus, since the fibers run all directions equally, there are no cold spots forming at panel edges or around screws and fasteners, which definitely improves how comfortable people feel inside the space.

Rock Wool vs. PIR/PUR: Energy Efficiency Comparison for Metal Roof and Wall Systems

PIR and PUR foams start off with better thermal conductivity numbers around 0.022 to 0.028 W/m·K compared to rock wool's 0.040 to 0.045 range, but rock wool actually performs better for long term energy efficiency in metal buildings. The problem with organic foams is they begin to break down once temperatures hit about 120 degrees Celsius, which happens regularly on metal roofs that get lots of sun exposure. This breakdown causes permanent loss of insulation effectiveness and might even lead to complete failure of the insulation system. Rock wool tells a different story though. Made from non-combustible minerals, it stays stable both dimensionally and thermally even at temperatures exceeding 1000 degrees Celsius, so it keeps working properly despite real-world heat challenges. Another big plus is how rock wool handles moisture. Unlike PIR and PUR materials that can lose as much as 20% of their insulating power when humidity gets involved, rock wool consistently maintains its thermal properties for many years. Industrial and commercial facilities with metal buildings looking to save money on energy costs over time while maintaining reliable operation should seriously consider switching to rock wool insulation instead.

Fire Safety Compliance: Why Rock Wool Sandwich Panels Meet A1 Requirements for Metal Structures

Non-Combustibility Certification (EN 13501-1) and Real-World Fire Containment in Warehouses

Rock wool sandwich panels get an A1 rating according to EN 13501-1, which is basically the top mark for fire safety in Europe. This happens because they're made entirely from minerals rather than organic stuff. The core material, made from basalt and slag, just won't catch fire, won't melt down, and doesn't give off any extra fuel or smoke if there's a blaze. Because these panels don't burn, they keep holding together even when temps go past 1000 degrees Celsius. That makes all the difference for buildings with steel frames during fires. Regular materials tend to give way quickly, but rock wool panels actually help support the structure instead of making things worse when everything else is already failing apart.

Warehouse owners who've actually put these materials to the test report impressive results when it comes to containing fires. Rock wool panels rated A1 do a great job at stopping flames and heat from spreading between different sections of a facility. These panels can hold up against intense fire conditions for around two hours during flashovers, which is pretty remarkable. Studies have found that warehouses equipped with A1 certified panels suffer about two-thirds less damage to their structures compared to places using materials that catch fire easily. Another big plus? Rock wool doesn't give off much toxic smoke at all. This matters a lot in tight industrial spaces where people need time to get out safely and where poor air quality could cause serious health problems. Combine these rock wool panels with traditional fire suppression systems like sprinklers, and facility managers end up with a comprehensive fire defense system that meets current safety standards and satisfies insurance companies looking for proper risk management practices.

Structural Integration and Weight Efficiency of Rock Wool Sandwich Panels in Prefabricated Metal Buildings

Load-Bearing Capacity, Deflection Limits, and Crane-Safe Installation Protocols

Rock wool sandwich panels offer impressive compressive strength starting at around 40 kPa combined with surprisingly low weight per square meter, typically below 20 kg/m². These characteristics make them great choices for walls and roofs in prefabricated metal structures where structural integrity matters most. The panels can handle substantial roof loads from snow accumulation, air conditioning equipment, even solar panel installations, all while keeping deflection rates well within acceptable limits of L/200. This means they stay stable over time despite various stress factors like strong winds, earthquakes, and regular structural weight. Because they're so light, installation goes much faster when using cranes with standard vacuum lifting techniques that protect the panels during transport and reduce damage risks on site. Construction projects using these panels often finish 40% quicker compared to conventional insulation methods. Plus, there's less strain on building foundations which cuts down on civil engineering work needed, something that makes a big difference in projects where both time and money are tight constraints.

Long-Term Durability of Rock Wool Sandwich Panels in Harsh Metal Building Environments

Galvanized Steel vs. Aluminum Facings: Corrosion Resistance in Coastal and Industrial Settings

How long rock wool sandwich panels last in harsh environments really depends on what kind of facing material gets chosen. Galvanized steel works great because it has that sacrificial zinc coating which fights off rust, especially important in places where there are lots of airborne chemicals and wear and tear. When specifiers go for heavy-duty stuff like AZ150 coatings, these panels can actually hold up for over 30 years even near the coast where salt spray is constantly attacking them. Aluminum faces things differently though. They form their own protective oxide layer naturally, which makes them pretty good at resisting corrosion from sea air. That's why they're so popular along coasts where maintenance costs stay low. But here's the catch: aluminum just doesn't take impacts as well as galvanized steel does. So in areas with lots of foot traffic or industrial activity, extra bracing might be needed. What both materials share is their ability to keep moisture out of the rock wool inside. This keeps the insulation working properly and maintains structural strength if everything is done right during installation. Most builders find either option works fine for most projects, depending on where they need to install them.

Table of Contents

- Thermal Insulation Performance of Rock Wool Sandwich Panels in Metal Building Envelopes

- Fire Safety Compliance: Why Rock Wool Sandwich Panels Meet A1 Requirements for Metal Structures

- Structural Integration and Weight Efficiency of Rock Wool Sandwich Panels in Prefabricated Metal Buildings

- Long-Term Durability of Rock Wool Sandwich Panels in Harsh Metal Building Environments