Among construction materials, rock wool sandwich panels are perhaps some of the best tools available towards achieving energy efficiency. It is important to note that these panels are eco-friendly, self-extinguishing, and have excellent insulation properties for thermal and sound. In this article, we examine how these panels improve energy efficiency in contemporary buildings.

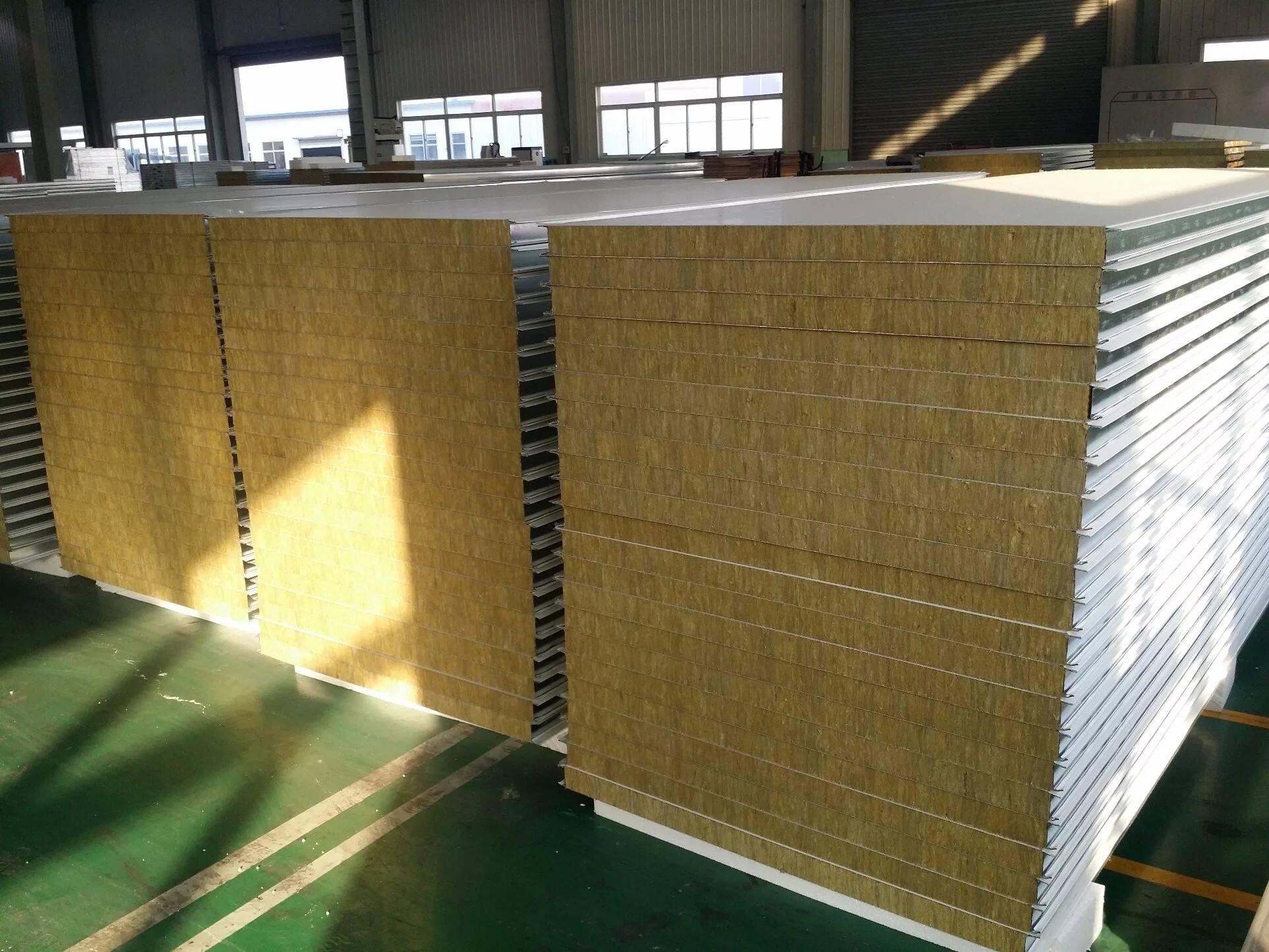

Rock wool sandwich panels consist of two skins of metal or other materials enclosing a previously prefabricated rock wool blanket. This type of composition helps the sandwich panels to achieve effective thermal insulation which in turn minimizes the heat loss windows endure during winter and helps maintain comfortable temperatures during summer. There is a growing urgency to find solutions that offer energy efficient buildings and this is particularly evident with the rocketing energy costs. In particular, utilizing rock wool sandwich panels in the construction of buildings can significantly increase energy savings.

The most distinguishing feature of sandwich panels rock wool is their ability to endure fire. The presence of combustible materials like polystyrene and plastics jeopardizes building safety. However, rock wool enhances safety because it is non-combustible. Due to the stringent regulations on the use of construction materials, polystyrene sandwich panels are an excellent choice for both commercial and residential constructions because they fulfill the requirements for fire resistance. Such regulations protect the occupants not only safeguard the building from unnecessary damage.

Moreover, rock wool sandwich panels contribute towards sustainable construction. The volcanic rock used to produce rock wool is natural; therefore, it is both abundant and eco-friendly. Additionally, these panels can be recycled at the end of life, reducing pollution caused by landfills. Building professionals looking to align their projects with sustainability and eco-friendly construction materials choose rock wool sandwich panels.

Changing to rock wool sandwich panels is very advantageous, especially in regard to the installation process. The pre-fabricated panels can be put together on site, which reduces both labor costs and construction time. This is important in large scale projects that are budget and time constrained. Moreover, the rock wool sandwich panels have lightweight characteristics which ease handling and transporting, thus saving time.

With proper rock wool sandwich panels, the energy efficiency is maintained throughout the structure because they are made and assembled with great care. Usage of energy-efficient building materials will be on the rise as the construction industry evolves. For efforts to combat climate change and in support of eco-friendly practices, sandwich panel manufacturers using rock wool will most likely become the industry standard. Their innovative designs and manufacturing processes will ensure that they remain unrivaled in energy efficient construction for a long time.

Unlike others, sandwich panels with rock wool cores have unique character traits. While redefining safety, these panels are also rightly energy-efficient and eco-friendly in modern construction. They assist both builders and regulators in understanding that energy-efficient structures can be constructed to satisfy market and consumer demands while meeting construction requirements. The adoption of these panels in construction practices that strive for environmental sustainability will lead the way toward improved energy-efficient architecture.