Rakennusalalla kehittyy jatkuvasti, kun EPS-kerrostaulut ovat noussut uudeksi valintaksi, jotka ovat helpot, taloudelliset ja tarjoavat korkean isoloinnin. Tässä artikkelissa käsitellään erilaisia EPS-kerrostaulujen etuja, jotka tekevät niistä modernin ratkaisun rakennuksille.

Kevyempi mutta vahva

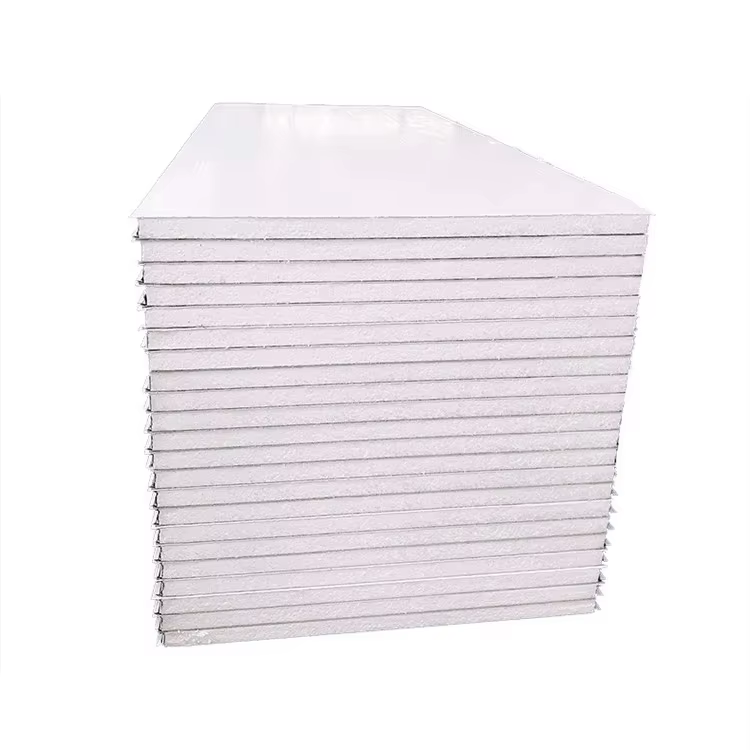

Rakennuspiireissä EPS-sandwich-paneelit erottuvat ensisijaisesti keveytensä ansiosta. Kyseessä on oleellisesti paneelijärjestelmä, jossa laajennetusta polystyreenistä muodostuu keskikerros, jota rajoittavat ulkopuolella vahvemmat materiaalit. Ulkokerrokset ovat painoltaan suuremmat kuin EPS-ydinosan oma paino, mutta ne tarjoavat kuitenkin koko paneelille yllättävän lujuuden. Tämä yhdistelmä vähentää kuljetuskustannuksia, sillä kaikki ei ole niin raskasta kuljetettavaksi, ja asennus on työntekijöille huomattavasti helpompaa. Myös urakoitsijat pitävät tästä hyödyllisestä ominaisuudesta. Kun on kyse tiukoista aikatauluista tai hankalasti lähestyttävistä kohteista, niin sellainen materiaali, joka ei vaadi lisätyövoimaa, tekee kaiken tehokkaammasta toteutumisesta mahdollista.

Tunnettu isoloinnista

Nämä paneelit todella pitävät mitä lupasivat eristysominaisuuksistaan, vähentäen energiankulutusta ja myös kuukausittaisia sähkölaskuja. Kun niitä käytetään yhdessä kylmäaineiden kanssa, ne muodostavat tehokkaan esteen lämmön leviämiselle. Tämä tarkoittaa, että vähemmän lämpöä karkaa seinien ja kattojen läpi. Lopputulos? Sekä asuinkiinteistöjen että toimistorakennusten lämmityskustannukset laskevat. Toimistot hyötyvät erityisesti, sillä miellyttävän lämpötilan ylläpitäminen on paljon helpompaa ilman, että termostaatteja tarvitsee säätää koko päivän ajan.

Kustannustehokkuus

Kun tarkastellaan rakennusmateriaaleja, kustannukset ovat yleensä ensimmäinen asia, johon ihmiset kiinnittävät huomiota. EPS-sandwichpaneelit tulevat kohtuullisella alkuhinnalla, ja ne säästävät rahaa pitkäaikaisesti, koska niiden huoltotarve on vähäistä ja ne toimivat energiatehokkaasti. Näistä paneeleista on myös melko kestäviä. Ne kestävät erilaisia säähaittoja kuten äärimmäistä kuumuutta ja voimakasta sadetta, mikä tarkoittaa, että rakennukset pysyvät suojattuina pidemmän ajan. Tämä kestävyys puolestaan lisää niiden arvoa ajan mittaan, mikä tekee niistä viisaan valinnan kaikille, jotka haluavat sekä laatua että taloudellisuutta rakennusprojekteihinsa.

Monipuolisuus sovelluksissa

EPS-kerrospaneelien monipuolisuus leviää koko teollisuuden läpi. Valikoima kattaa asuinrakennukset, kaupalliset rakennukset tai jopa teollisuusrakenteet. Koska nämä paneelit ovat sovellettuja moniin käyttötarkoituksiin, niiden rakenteellinen ja lämpötilateho varmistaa, että rakentajat ja arkkitehdit voivat toteuttaa rohkeita suunnitelmia samalla kun säilyttävät vaaditut turvallisuusnormit.

Ympäristöystävällinen

Rakennusteollisuus kohtaa kestävyyskäytännöissä haasteita kuin ei koskaan aiemmin. Kun valmistajat valmistavat EPS-kiilapaneloita kierrätysmateriaaleista, tällaiset tuotteet täyttävät automaattisesti ympäristöystävällisen vaihtoehdon kriteerit rakentajille. Panelit itse ovat myös melko hyviä energiansäästäjä. Rakenteet, jotka on rakennettu näistä materiaaleista, päätyvät ajan myötä tuottamaan vähemmän hiilidioksidipäästöjä verrattuna perinteisiin vaihtoehtoihin. Tämä on järkeä, kun tarkastellaan maailmanlaajuisia ponnistuksia rakennusteollisuuden viherrystä eri maiden välillä.

Teollisuuden kehitys ja tulevaisuuden näkymät

Kun rakennukset tulevat energiatehokkaammiksi ja kustannustehokkuutta korostavammiksi, EPS-sandwichpaneelit vaikuttavat löytävän lisääntyvää hyväksyntää rakennusteollisuudessa. Valmistajat sijoittavat resursseja tuotantomenetelmien hiontaan samalla kun neuvottellaan innovaatioita, kuten parannettuja eristysominaisuuksia ja nopeampia asennustekniikoita. Monet alan ammattilaiset ovat alkaneet sisällyttää nämä paneelit suunnitelmiaan, koska ne tarjoavat sekä rakenteellista kantavuutta että lämpöominaisuuksien hyötyjä. Jatkuvien kehitysten myötä niistä on tullut helpompia käsitellä ja edullisempia kuin perinteiset vaihtoehdot, joten ei ole yllätys, että rakennusyritykset, sekä asuinkerrostalojen että kaupallisten urakoitsijoiden, käyttävät yhä enemmän EPS-sandwichpaneeleita monenlaisten sovellusten alalla.