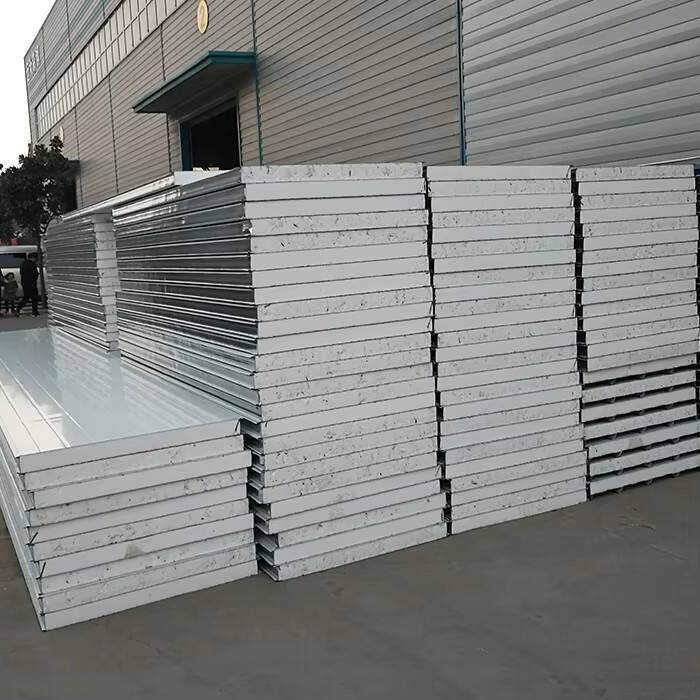

EPS sandwich panel building materials are composite structures consisting of an expanded polystyrene (EPS) foam core bonded between two facing materials, designed to provide insulation, structural support, and weather resistance in construction. The EPS core, created by expanding polystyrene beads with steam, forms a lightweight, closed cell foam with excellent thermal insulation properties, making it ideal for reducing heat transfer in walls, roofs, and floors. Facing materials vary based on application needs: galvanized steel is common for durability and weather resistance in industrial or commercial buildings; aluminum offers corrosion resistance for coastal areas; fiberglass reinforced plastic provides lightweight strength for residential use; and cementitious boards enhance fire resistance. Adhesives used to bond the core and facings are formulated for strong, durable bonds that withstand temperature fluctuations and moisture. These materials combine to create panels with high strength to weight ratios, easy installation, and cost effectiveness. The closed cell structure of EPS resists moisture absorption, while facings protect the core from physical damage and UV radiation. EPS sandwich panels are available in various thicknesses (50mm to 250mm) to meet thermal performance requirements across different climates. As building materials, they contribute to energy efficient construction by reducing heating and cooling demands, while their modular nature accelerates construction timelines. Compliance with material standards ensures consistent quality, making EPS sandwich panels a versatile choice for sustainable, high performance buildings.