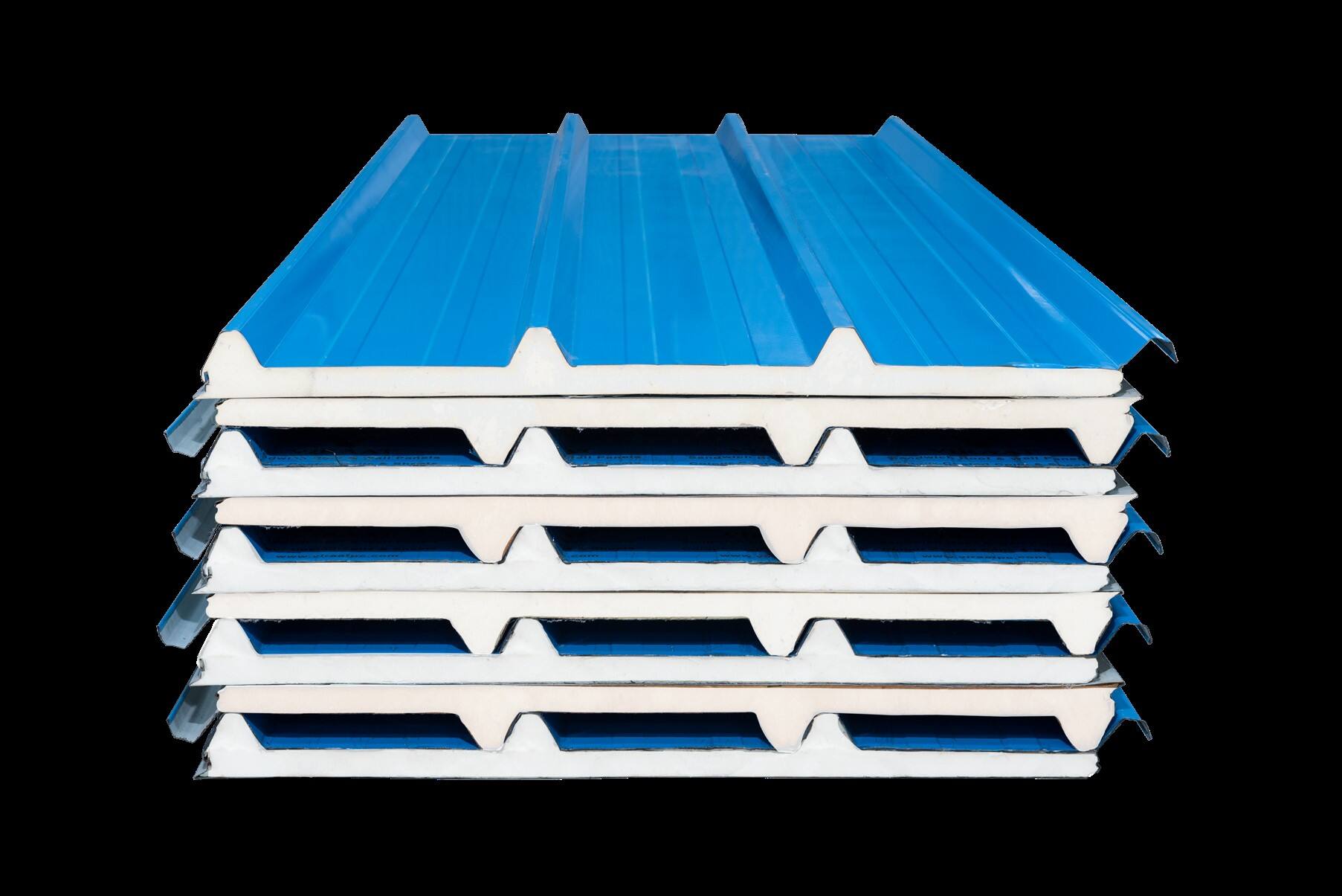

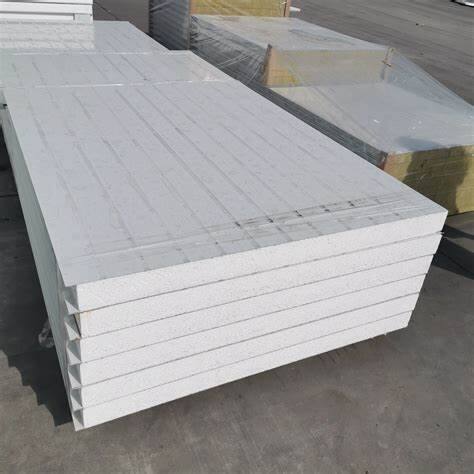

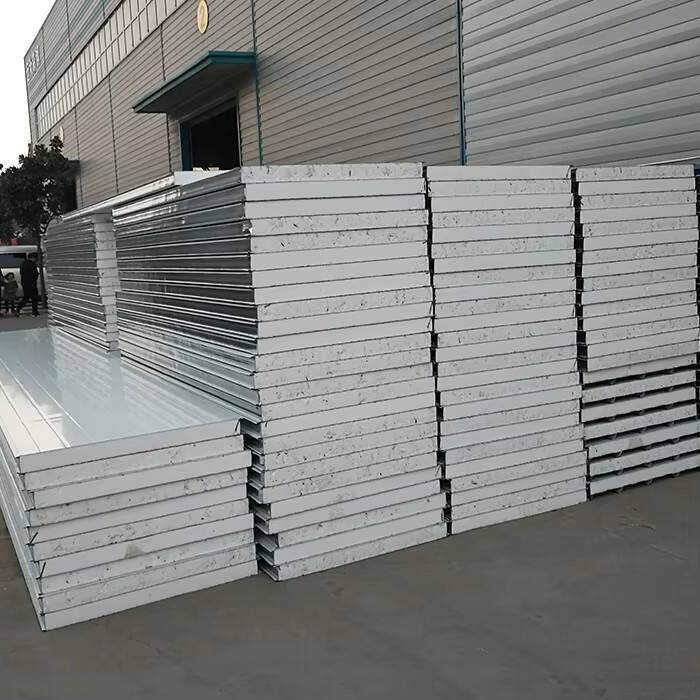

Low density EPS (Expanded Polystyrene) panel is a lightweight insulation material composed of expanded polystyrene foam with a lower density, typically ranging from 10 to 30 kg/m³, offering excellent thermal insulation and cushioning properties for various construction and packaging applications. The low density results from a higher volume of air pockets within the foam structure, which enhances its insulating capabilities by reducing heat transfer through conduction. These panels are valued for their lightweight nature, making them easy to handle, transport, and install in walls, roofs, and floors of residential and commercial buildings. Their flexibility allows them to conform to irregular surfaces, while their closed cell structure provides moderate water resistance and prevents moisture absorption, though they are often faced with vapor barriers for enhanced protection in humid environments. In construction, low density EPS panels are used for thermal insulation in cavity walls, underfloor heating systems, and roof insulation, contributing to energy efficient buildings by reducing heating and cooling costs. They also find applications in packaging, where their cushioning properties protect fragile items during transportation. Manufactured through a process of expanding polystyrene beads with steam, these panels are cost effective, recyclable, and resistant to rot, pests, and chemical degradation, making them a versatile choice for insulation and protection needs where weight and thermal performance are priorities.