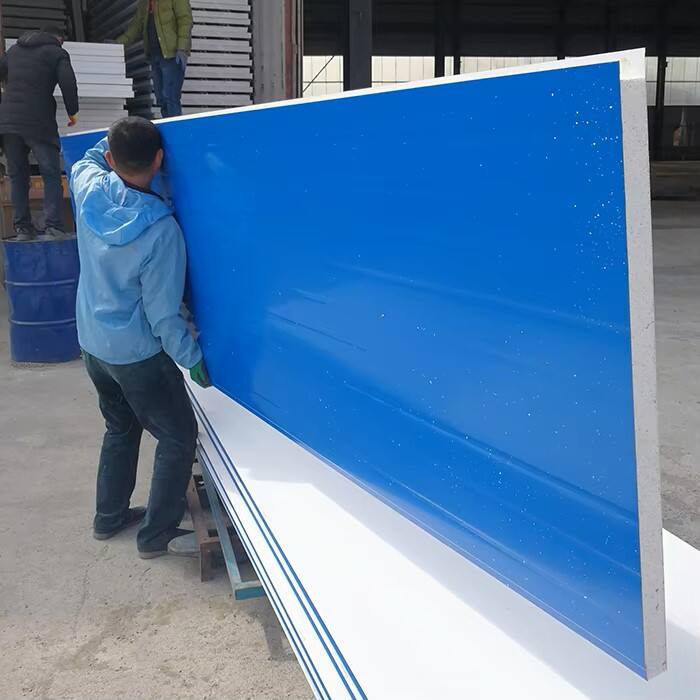

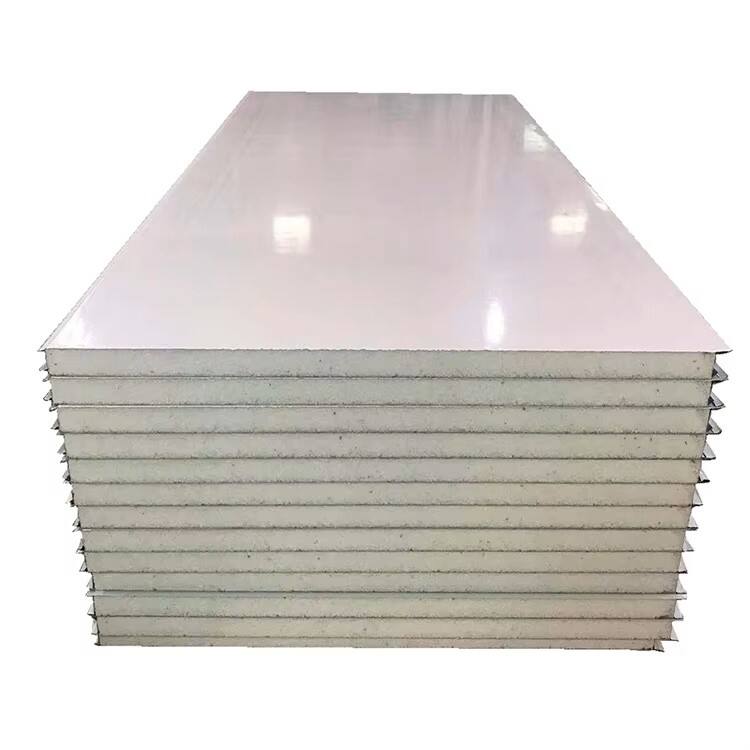

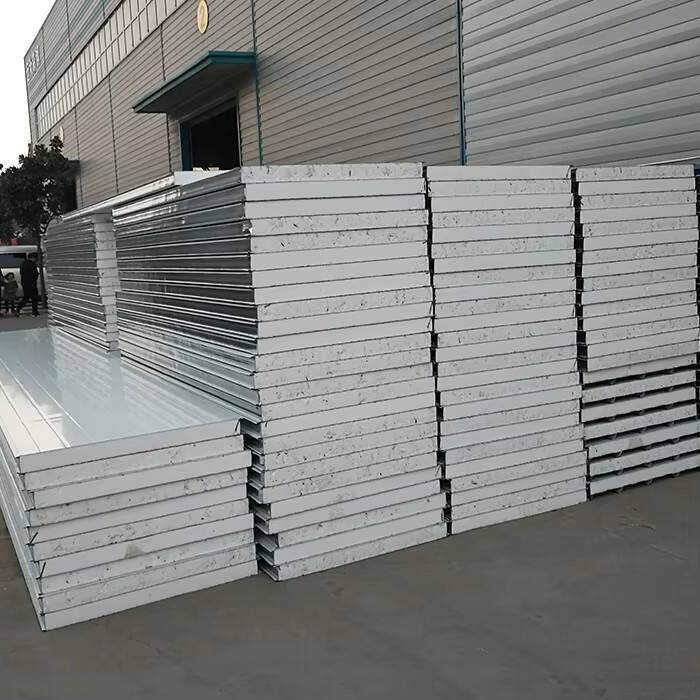

Sound absorbing EPS panels are specialized insulation materials designed to reduce noise transmission by absorbing sound waves, making them ideal for creating quieter indoor environments in residential, commercial, and industrial settings. These panels feature an EPS foam core with a porous or textured structure that traps and dissipates sound energy, rather than reflecting it, effectively lowering reverberation and airborne noise. The sound absorption capability is enhanced by the foam’s cellular structure, which creates millions of tiny air pockets that disrupt sound wave propagation. Manufacturers often optimize the density and porosity of the EPS core to target specific frequency ranges, from low frequency machinery noise to high frequency speech or traffic sounds. Facing materials, such as perforated metal or acoustic fabric, can further improve sound absorption by allowing sound waves to penetrate into the foam core while providing structural protection. These panels are commonly used in wall partitions, ceilings, and floors of recording studios, offices, schools, hospitals, and manufacturing facilities, where noise control is essential for comfort, productivity, and regulatory compliance. Beyond sound absorption, they retain the thermal insulation properties of standard EPS panels, offering dual functionality that reduces both noise and energy costs. Installation is straightforward, with panels easily cut to size and installed using adhesives or mechanical fasteners. Sound absorbing EPS panels provide a cost effective alternative to traditional acoustic materials like mineral wool, combining lightweight handling, durability, and versatility to address diverse noise reduction needs in modern buildings.