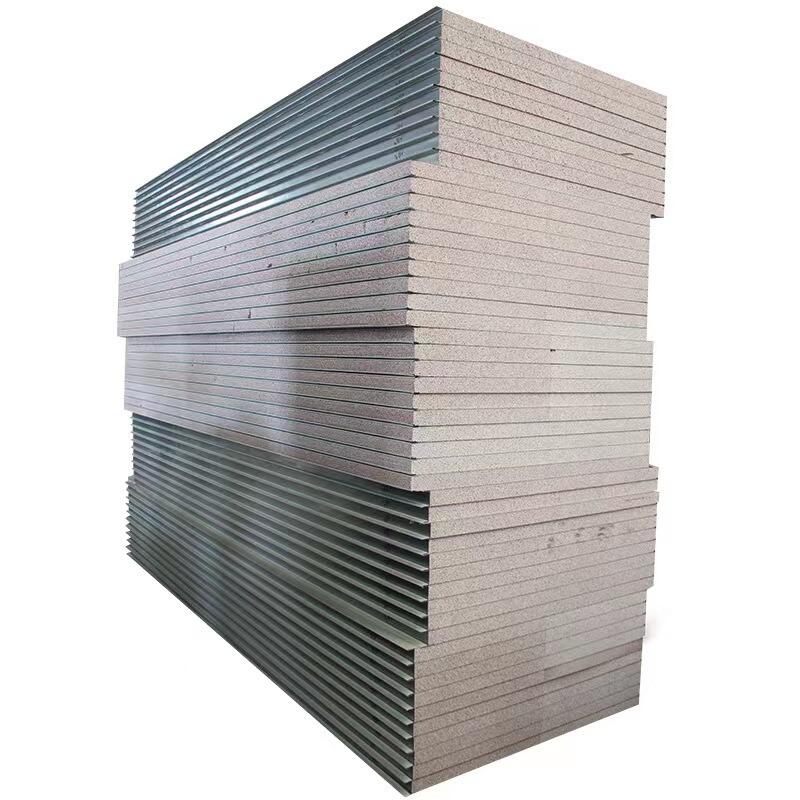

Standard size EPS panels are pre manufactured insulation panels with consistent dimensions, typically ranging from 1.2m to 1.5m in width and 2.4m to 6m in length, designed for efficient construction and universal compatibility across building projects. These panels feature an expanded polystyrene (EPS) foam core sandwiched between facing materials like steel, aluminum, or fiberglass, ensuring uniform quality and performance. The standardization of sizes streamlines the construction process, as builders can easily calculate material quantities, reduce waste from cutting, and accelerate installation by leveraging pre fit dimensions. This consistency is particularly valuable for large scale projects such as residential complexes, commercial buildings, and industrial warehouses, where speed and precision are critical. Standard size EPS panels offer reliable thermal insulation, with thermal conductivity values typically between 0.032 and 0.040 W/(m·K), making them effective for energy efficient construction. Their lightweight nature reduces structural load, while the rigid foam core provides good compressive strength for floor and roof applications. Manufacturers often produce these panels with standardized thicknesses, from 25mm to 200mm, allowing builders to select the appropriate insulation level based on climate requirements. Compliance with industry standards ensures that standard size EPS panels meet safety and performance criteria, including fire resistance (when treated with flame retardants) and moisture resistance. For contractors and developers, these panels represent a cost effective solution that balances quality, efficiency, and ease of use, making them a staple in modern construction practices worldwide.