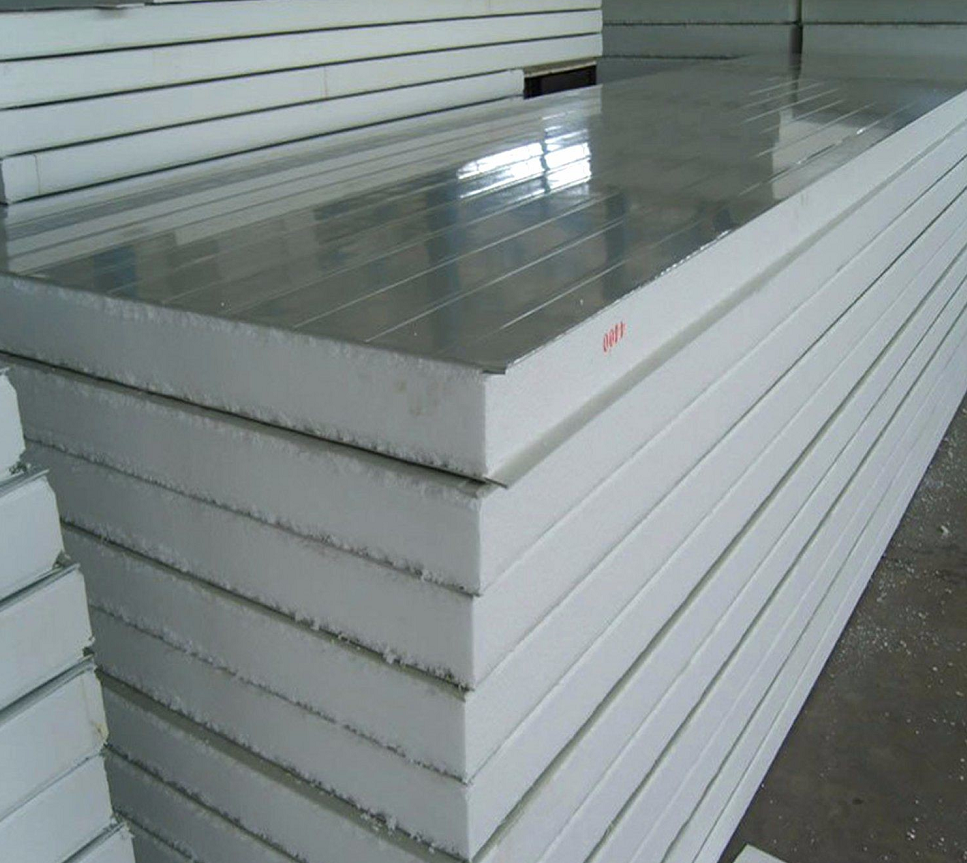

EPS Sandwich Panel Composition and Structure Explained

EPS sandwich panels are built with three main parts: protective outer layers and an insulating middle section. Most often, these outer layers are made of either galvanized steel or aluminum, wrapping around an expanded polystyrene core. What this setup does is combine strength with good thermal properties. The EPS itself can handle quite a bit of compression force, but without those strong outer skins, it would just get damaged easily when exposed to weather conditions or physical impacts over time.

| Component | Function | Typical Materials |

|---|---|---|

| Outer Facings | Structural support & protection | Galvanized steel, Aluminum |

| Core Material | Thermal insulation & load distribution | Expanded Polystyrene (EPS) |

| Adhesive Layer | Bonds materials securely | Polyurethane-based resins |

Core Materials: Expanded Polystyrene (EPS) Insulation Properties

EPS has this neat closed cell structure where it actually holds about 98 percent air inside those little polystyrene beads. This gives it an R value somewhere between 3.6 and 4.2 per inch thick material. That's pretty good when compared to pricier options such as XPS foam boards especially when things get below freezing point according to some recent research from Insulation Materials Analysis back in 2023. Fibrous types of insulation just don't hold up well against moisture but EPS stands out here since it barely soaks anything in. Tests show less than 2 percent water gets absorbed even under strict ISO 29767 standards. And this matters a lot because without proper protection against dampness, heat can escape through gaps in cold storage facilities where humidity levels tend to be high all year round.

Facings and Bonding: How Insulated Metal Panels Are Constructed

The bonding of metal facings to expanded polystyrene (EPS) cores happens via continuous lamination techniques, resulting in panels that can handle temperature extremes ranging between minus 40 degrees Celsius all the way up to plus 80 degrees. What makes this approach so effective is the consistent bond strength achieved during production, typically exceeding 150 kilopascals according to European standard EN 14509. These strong bonds prevent any air gaps that would otherwise reduce insulation effectiveness. For applications like seafood freezing facilities where moisture is a constant concern, aluminum facing materials resist corrosion better than alternatives. Meanwhile warehouses dealing with heavy foot traffic often opt for steel faced panels since they hold up much longer against wear and tear from daily operations.

Thermal Insulation Properties of EPS Panels in Cold Environments

In -25°C cold rooms, EPS maintains 94% of its initial R-value after ten years of use (Cold Chain Infrastructure Report, 2022), outperforming mineral wool (87% retention). Its hydrophobic nature prevents ice formation within panel cavities, and its thermal conductivity remains stable at ¥0.034 W/mK across freeze-thaw cycles.

Thermal performance (R-value) of EPS: How it compares to XPS and PIR

EPS sandwich panels typically have thermal conductivity ranging from about 0.032 to 0.038 W/mK, which gives them an R value somewhere around 3.6 to 4.2 per inch. That's actually a bit less than what we see with extruded polystyrene or XPS materials, which can hit R values between 4.5 and 5.0 per inch. Polyisocyanurate boards take things even further with their impressive R values reaching 6.0 to 6.8 per inch. But here's something interesting from industry tests: when temperatures drop to minus 20 degrees Celsius, EPS panels still hold onto about 94% of their insulating power. This makes them pretty good options for cold storage facilities despite not having the highest R values on the market.

| Material | Thermal Conductivity (W/m•K) | R-Value per Inch | Cost per m² ($) |

|---|---|---|---|

| EPS | 0.032–0.038 | 3.6–4.2 | 18–25 |

| XPS | 0.029–0.033 | 4.5–5.0 | 28–37 |

| PIR | 0.022–0.026 | 6.0–6.8 | 34–45 |

Efficiency and stability of EPS under prolonged cold storage conditions

Weathering simulations (Frontiers, 2024) reveal EPS panels experience only 5.1% bond strength reduction after 50 thermal cycles (-30°C to 20°C), demonstrating superior resilience to temperature fluctuations compared to traditional insulations. The closed-cell structure also minimizes air infiltration, preserving thermal performance even during extended power outages in freezer facilities.

Long-term thermal conductivity and resistance to performance drift

Field data from 12 commercial cold stores (2018–2023) indicates EPS insulation exhibits less than 0.5% annual R-value loss when properly sealed—on par with XPS (0.3%) and better than mineral wool (1.2%). Vapor barrier integration plays a key role, reducing moisture-related conductivity increases by 63% over a decade.

Debunking the myth: Is EPS underperforming in real-world cold chains?

Even though EPS has a lower R-value per inch compared to other materials, real world data from cold storage facilities operating at -25 degrees Celsius indicates similar energy expenses as those insulated with XPS when 15 centimeter thick EPS panels are used. Installation takes about 30 percent less time, and upfront costs can be as much as 40 percent cheaper. These numbers make EPS pretty attractive for many businesses, especially in regions still building out infrastructure. Where money is tight and electricity supply isn't always reliable, being able to get things set up quickly and spend less money upfront makes all the difference. That's why we're seeing more adoption in emerging markets across Southeast Asia and parts of Africa where these practical advantages really matter.

Challenges of Moisture and Vapor Drive in Cold Storage Environments

Temperature differentials between interior spaces (-20°C to 4°C) and external environments drive vapor migration into wall cavities, increasing the risk of EPS core saturation. Research indicates just 1% moisture infiltration can reduce insulation efficiency by 7% (Building Science Corp., 2022), underscoring the importance of effective vapor control.

Vapor Barriers and Sealing Techniques for EPS Sandwich Panel Integrity

Advanced sealing systems maintain panel integrity through three primary mechanisms:

- Continuous membranes: Aluminum foil facings serve as vapor retarders (0.05 perm rating)

- Edge sealing: Polyurethane-based sealants prevent capillary action at joints

- Thermal breaks: Insulated gaskets reduce condensation risks by 63% compared to bare metal connections

Case Study: Proven Durability of EPS Panels in High-Humidity Cold Rooms

A seafood processing facility in Southeast Asia tested EPS sandwich panels under 85% ambient humidity:

| Metric | 5-Year Performance | Industry Benchmark |

|---|---|---|

| R-value retention | 94% | 82% |

| Surface condensation | 12 incidents/year | 45 incidents/year |

| Maintenance costs | $8.2k/year | $18.7k/year |

Using 150mm EPS panels with double-sided vapor barriers, the project demonstrated that effective moisture management delivers superior long-term performance regardless of climate.

Cost Effectiveness and Installation Benefits for Cold Storage Projects

Affordability of EPS Sandwich Panels vs. Premium Insulation Alternatives

EPS sandwich panels offer a 30–50% cost advantage over premium options like PIR or XPS. The simplicity of EPS manufacturing reduces material expenses, and while PIR provides higher R-values per inch (R-6.5 vs. R-4), EPS compensates through scalable thickness options without sacrificing structural performance at -30°C.

Faster, Modular Installation Reducing Construction Timelines

Pre-fabricated EPS panels accelerate construction via:

- Plug-and-play assembly: Interlocking tongue-and-groove joints allow daily installation of 50–70 m² of wall space, nearly double the rate of traditional insulated concrete walls

- No curing delays: Eliminates 3–7 day waiting periods associated with wet trades

- Lightweight handling: At 18 kg/m², panels require less heavy lifting equipment than mineral wool alternatives (45 kg/m²)

This efficiency shortens total project timelines by 30–40%, a crucial advantage for perishable goods facilities operating on tight schedules.

Lifecycle Cost Analysis: Balancing Initial Savings With Long-Term Reliability

A 2023 ROI study found that although EPS systems have 18% lower upfront costs than PIR, their 20-year lifecycle costs are comparable due to:

- Reduced thermal bridging: Continuous foam core maintains 94% design R-value versus 89% in fibrous insulation

- Moisture resistance: <1% water absorption prevents the typical 0.5% R-value drop per percentage point of moisture gain

- Durability: EPS retains 95% compressive strength (70–100 kPa) after 50 freeze-thaw cycles, supporting high-traffic freezer operations

Optimizing panel thickness (100–150mm for -25°C environments) ensures long-term thermal consistency while managing initial investment.

Proven Applications and Industry Adoption of EPS Sandwich Panels

EPS Panels in Commercial Refrigerated Warehouses and Distribution Centers

EPS sandwich panels have become pretty much standard in today's cold chain facilities across North America and Europe, where about 60% of newly built refrigerated warehouses specify these panels for their walls and ceilings. The reason? They offer excellent thermal performance, roughly R-4.35 per inch, while still maintaining good structural integrity needed for those temperature sensitive logistics operations. Looking at the bigger picture globally, around 42% of all cold storage wall installations worldwide actually use EPS material, which has overtaken many traditional options especially in regions where budget considerations play a major role in construction decisions.

Use in Food Processing Plants and Low-Temperature Blast Freezers

Food manufacturers increasingly select EPS panels for areas requiring -30°C operation. The material’s closed-cell structure resists moisture absorption—a major benefit in high-humidity processing zones. Real-world projects in seafood facilities show EPS maintaining <0.5% variation in thermal conductivity after five years, outperforming some premium alternatives under continuous use.

Optimizing Panel Thickness for Different Temperature Zones

| Temperature Requirement | Recommended EPS Thickness | Energy Savings vs. Standard Build |

|---|---|---|

| +2°C to +8°C (Coolers) | 100–150mm | 18–22% |

| -18°C (Freezers) | 150–200mm | 25–30% |

| -25°C to -30°C (Blast) | 200–250mm | 32–38% |

This strategic approach has reduced energy consumption by 29% in ASEAN cold storage developments while meeting ISO 23953 standards.

Growing Adoption in Developing Markets: Trends and Success Stories

Market forecasts indicate the global EPS sandwich panel industry could hit around $1.45 billion by 2032, largely driven by explosive growth across Asia-Pacific markets. Since 2020 alone, this region has grabbed nearly 58% of all new market territory. Looking at specific applications, India's cold chain development program shows impressive adoption rates too. About 73% of newly built facilities there are incorporating EPS panels these days, cutting down construction time by roughly 40% compared to traditional methods. The cost savings story continues elsewhere as well. Logistics hubs throughout the Middle East have found their operating expenses drop by approximately 19% when switching from mineral wool to EPS systems for insulation needs.

Table of Contents

- EPS Sandwich Panel Composition and Structure Explained

- Core Materials: Expanded Polystyrene (EPS) Insulation Properties

- Facings and Bonding: How Insulated Metal Panels Are Constructed

- Thermal Insulation Properties of EPS Panels in Cold Environments

- Thermal performance (R-value) of EPS: How it compares to XPS and PIR

- Efficiency and stability of EPS under prolonged cold storage conditions

- Long-term thermal conductivity and resistance to performance drift

- Debunking the myth: Is EPS underperforming in real-world cold chains?

- Challenges of Moisture and Vapor Drive in Cold Storage Environments

- Vapor Barriers and Sealing Techniques for EPS Sandwich Panel Integrity

- Case Study: Proven Durability of EPS Panels in High-Humidity Cold Rooms

- Cost Effectiveness and Installation Benefits for Cold Storage Projects

- Proven Applications and Industry Adoption of EPS Sandwich Panels