Understanding the Core: Polyurethane (PU) and Its Insulation Advantages

PU sandwich panels offer exceptional thermal performance thanks to their unique closed cell foam core design. These panels have a thermal conductivity rating around 0.022 W/mK, which ranks among the best available for insulation materials today. Studies from 2024 show that PU cores actually block about 97% of heat movement through building walls and roofs. What does this mean practically? The R values reach approximately 6.3 per inch thickness, making them far better at keeping buildings at consistent temperatures compared to most other insulation types currently on the market.

What Makes Polyurethane (PUR) Core Ideal for Thermal Insulation?

The gas-filled cellular structure of rigid PU foam creates millions of microscopic air pockets that disrupt convective and conductive heat flow. Unlike open-cell alternatives, this closed-cell design minimizes moisture absorption (<2% water uptake) while achieving compressive strengths of 200–300 kPa, contributing to structural stability.

Comparing PU with PIR, EPS, and Mineral Wool Cores

When benchmarked against common alternatives:

| Material | λ-Value (W/mK) | Fire Rating | Density (kg/m³) |

|---|---|---|---|

| PU | 0.022–0.028 | B-s1,d0 | 35–50 |

| PIR | 0.023–0.029 | B-s1,d0 | 40–55 |

| EPS | 0.033–0.038 | E-d2 | 15–30 |

| Mineral Wool | 0.035–0.045 | A1 | 40–160 |

PU provides the optimal balance of thermal resistance and mechanical performance for most construction applications.

Core Thickness, U-Value, and λ-Value: Measuring Thermal Performance

U-value calculations confirm that 100mm PU panels (U = 0.22 W/m²K) match the insulation capacity of 150mm mineral wool assemblies. Thinner PU profiles enable slimmer wall constructions while meeting EN 14509 thermal requirements for low-energy buildings.

Acoustic Insulation Properties of PU Sandwich Panels

The viscoelastic polymer matrix provides 28–32 dB sound reduction (tested per ISO 10140), effectively dampening high-frequency noise from rain, HVAC systems, and industrial equipment. Combined with airtight panel joints, PU assemblies achieve Rw+Ctr 40–45 ratings in partition wall configurations.

For projects requiring maximum thermal efficiency, third-party testing validates that PU sandwich panels reduce HVAC energy costs by 34–41% compared to traditional masonry construction.

Fire Safety and Compliance: Evaluating PU Panel Fire Ratings

Understanding Fire Resistance Classifications (e.g., Euroclass B-s1,d0)

The fire resistance ratings for PU sandwich panels are categorized using systems like Euroclass B-s1,d0 which basically tell us three important things about their performance during fires. First there's flame spread designated by the letter B, then we look at smoke production marked as s1, and finally whether they produce flaming droplets indicated by d0. These classifications come from strict testing procedures including standards like ASTM E84 and UL 263 that manufacturers must follow. Take for example a standard 100mm thick PU panel. When tested according to ASTM E119 wall assembly requirements, this panel can hold up structurally for one full hour even when exposed to temperatures reaching around 1000 degrees Celsius. That kind of endurance makes them suitable for many construction applications where fire safety is a concern. (Underwriters Laboratories reported similar findings back in 2023)

| Test Standard | Key Measurement | Typical PU Panel Performance |

|---|---|---|

| ASTM E84 | Flame spread index | © 25 (Class A) |

| EN 13501-1 | Smoke opacity (s1) | < 10% visibility loss |

| ISO 9705 | Heat release rate | < 250 kW/m² |

Modern Fire-Retardant PU Cores: Balancing Safety and Performance

Leading manufacturers now incorporate halogen-free additives like phosphorous compounds that reduce peak heat release rates by 40–60% compared to standard PU foams. This innovation allows 120mm panels to achieve Euroclass B ratings while maintaining λ-values of 0.022 W/mK–outperforming mineral wool alternatives in thermal efficiency by 27% (Ponemon Institute 2023).

Addressing Misconceptions About PU Panel Flammability

Contrary to outdated beliefs, modern PU cores self-extinguish within 15 seconds of flame removal in DIN 4102 tests. Accelerated aging studies show fire resistance properties remain stable for 25+ years when panels have UV-resistant steel facings–a critical factor for facade applications in desert climates.

Structural Performance and Environmental Durability

Load-Bearing Capacity for Roof and Wall Applications

Polyurethane sandwich panels have pretty good strength for their weight because they're made with different materials layered together. The middle part usually has a density around 40 to 50 kg per cubic meter. When it comes to actual building, these panels can span about 6 meters across walls and still hold up fine, though for roofs they work best at around 3.5 meters before needing extra support. According to research published last year by the International Panel Association, tests showed that PU panels handle compression forces between 250 and 400 kilopascals. That's actually quite impressive when compared to other options like expanded polystyrene or mineral wool boards. The numbers suggest PU panels beat those alternatives by roughly 30 to 50 percent when looking at similar thickness levels.

Panel Rigidity and Span Under Dynamic Loads

The closed-cell structure of polyurethane cores provides rigid support under dynamic loads like wind uplift (up to 1.5 kN/m²) and seismic activity. Tests under ASTM E330 standards reveal less than 2mm deflection at mid-span when subjected to 120% design loads, critical for industrial facilities in high-wind regions.

Performance in Extreme Climates: Arctic, Tropical, and Coastal Environments

PU sandwich panels retain thermal efficiency across temperature extremes:

- Arctic: Maintain R-values of 5.7 per inch at -40°C

- Tropical: Resist 95% humidity cycling without core degradation

- Coastal: Pass 5,000-hour salt spray tests with ©0.2% corrosion

UV Resistance and Long-Term Facade Durability

UV-stabilized polymer-coated steel facings on PU panels show 98% color retention after 15 years in accelerated weathering tests (ISO 4892-3). The non-porous PU core prevents moisture ingress, a key factor in achieving 25+ year lifespans for exterior applications.

Cost-Effectiveness and Return on Investment

Initial Cost vs. Lifecycle Savings of PU Sandwich Panels

PU sandwich panels do cost about 15 to 20 percent more initially than EPS options, but they really pay off in the long run. The insulation properties are just so much better that buildings using them save around 35 to 40 percent on energy bills according to this report from the 2024 Industrial Insulation Market. When looking at what happens over time, these panels actually make up for their higher price tag pretty quickly. Most studies show that within just 3 to 5 years, the money saved on heating and cooling systems covers the extra investment. And it doesn't stop there either. Eight out of ten building owners who switched to PU panels say they're saving well over four grand each year for every 10 thousand square feet of space they manage.

ROI in Refrigeration, Cold Storage, and HVAC Applications

PU panels excel in applications requiring strict temperature control:

| Application | Energy Savings | Payback Period |

|---|---|---|

| Industrial Cold Storage | 42–48% | 2.8 years |

| Commercial Refrigeration | 38–45% | 3.1 years |

| HVAC-Integrated Walls | 30–35% | 4.2 years |

The 2025 Building Materials ROI Study highlights that 72% of refrigeration facilities using PU panels reduced maintenance costs by 22% annually, achieving full ROI 18 months faster than mineral wool installations.

Application-Specific Selection and Installation Benefits

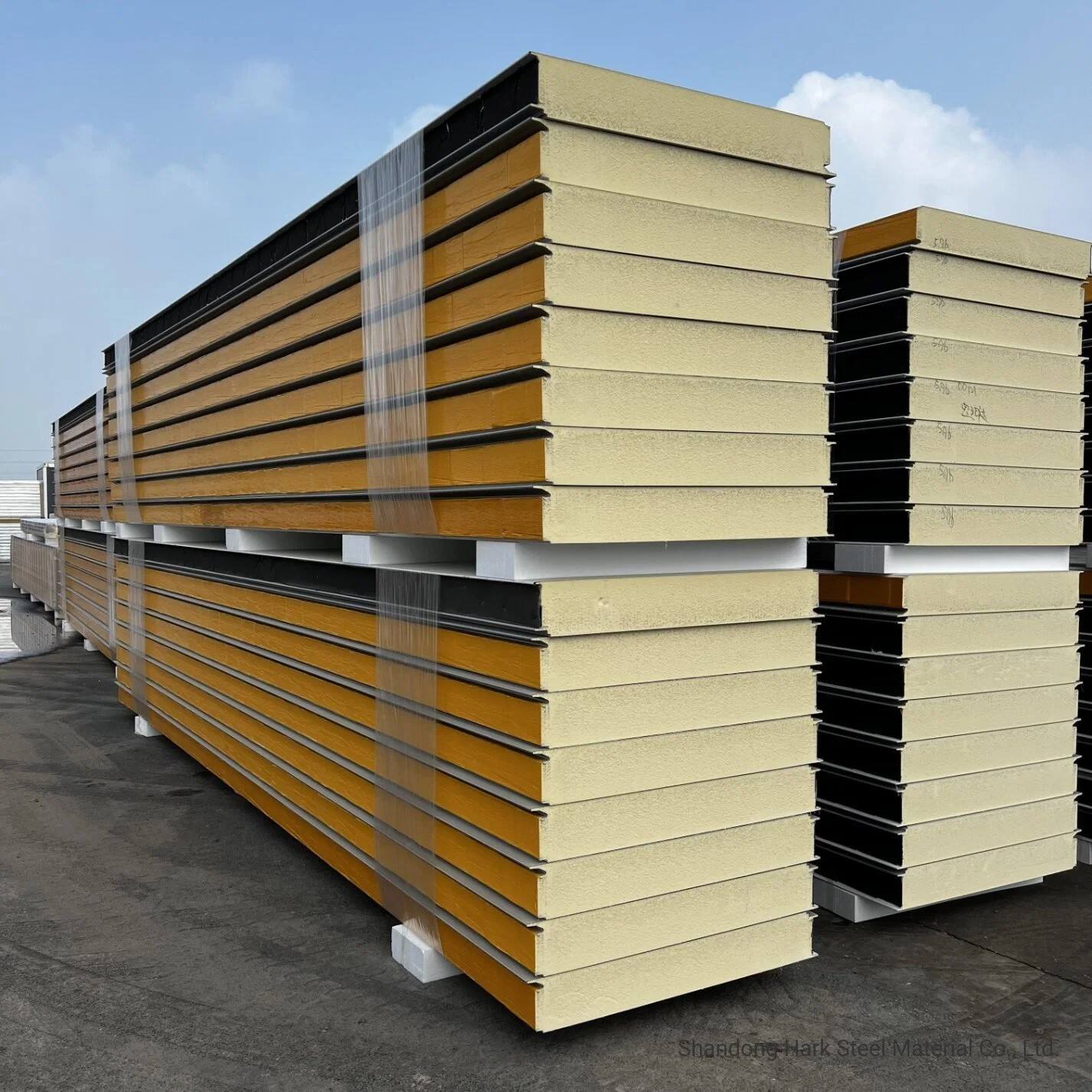

Best Uses for PU Sandwich Panels: Facades, Roofs, and Cold Rooms

PU sandwich panels excel in three primary applications due to their unique thermal and structural properties:

| Application | Key Benefit | Thermal Efficiency (U-Value)* |

|---|---|---|

| Building Facades | Weather resistance + design flexibility | © 0.28 W/m²K |

| Roof Systems | Load-bearing capacity + insulation | © 0.22 W/m²K |

| Cold Storage | Temperature retention + air-tightness | © 0.18 W/m²K |

| *Based on 2023 insulation studies of PU cores |

For facade projects, panels with PU cores reduce heat transfer by 25–35% compared to conventional materials while enabling curved and angular designs.

Modular Design and Fast Installation in Time-Sensitive Projects

Pre-engineered PU panels reduce installation timelines by up to 40% through standardized sizing and interlocking mechanisms. A 2022 warehouse project demonstrated that 10,000 m² of PU roof panels could be installed in 8 days versus 14 days for alternative materials.

Technical Features That Improve On-Site Assembly Efficiency

Key innovations include:

- Pre-fabricated tongue-and-groove joints eliminating onsite welding

- Integrated vapor barriers reducing secondary sealing work

- Lightweight panels (15–22 kg/m²) requiring smaller crews

Leading manufacturers now embed alignment markers and numbered assembly sequences directly into panel surfaces, minimizing measurement errors during rapid installations.

Frequently Asked Questions

What is the main advantage of Polyurethane (PU) sandwich panels?

PU sandwich panels offer exceptional thermal insulation, acoustic benefits, and durability, making them ideal for various construction applications.

How do PU panels compare to other insulation materials?

PU panels provide superior thermal performance compared to materials like PIR, EPS, and Mineral Wool due to their low thermal conductivity and structural stability.

Are PU panels safe in terms of fire resistance?

Yes, modern PU panels are designed with fire-retardant cores, achieving high fire resistance ratings such as Euroclass B-s1,d0.

Do PU sandwich panels offer a good ROI?

Yes, despite higher initial costs, PU panels deliver significant energy savings over time, achieving complete ROI faster than many other materials.

Table of Contents

- Understanding the Core: Polyurethane (PU) and Its Insulation Advantages

- Fire Safety and Compliance: Evaluating PU Panel Fire Ratings

- Structural Performance and Environmental Durability

- Cost-Effectiveness and Return on Investment

- Application-Specific Selection and Installation Benefits

- Frequently Asked Questions