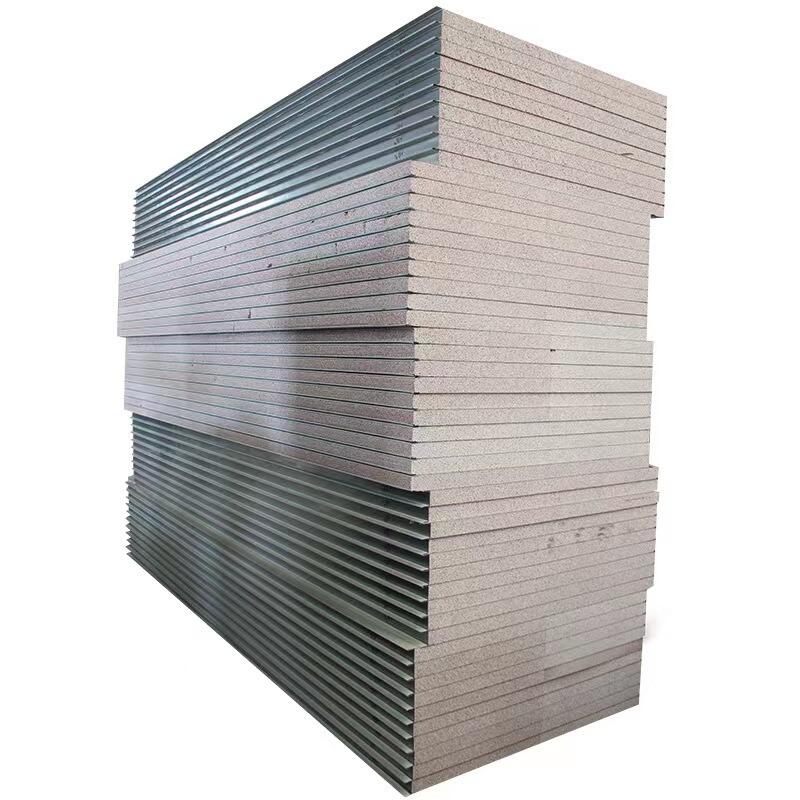

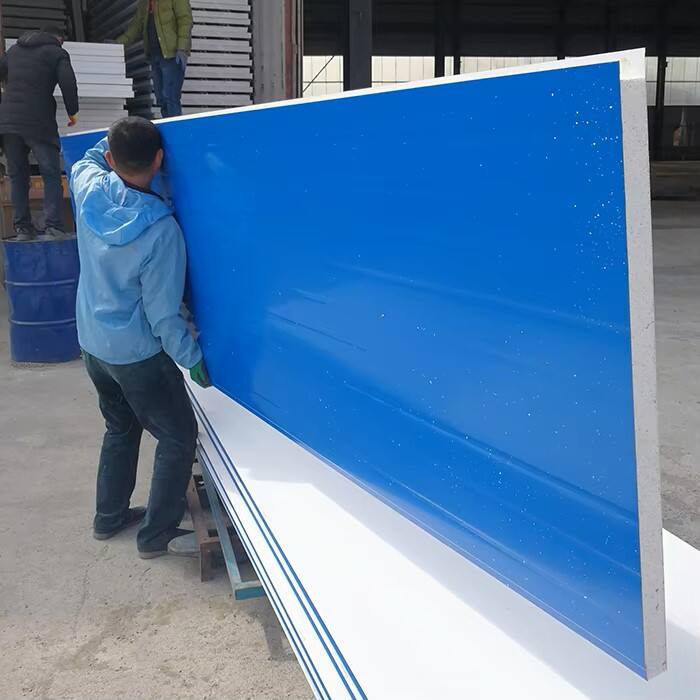

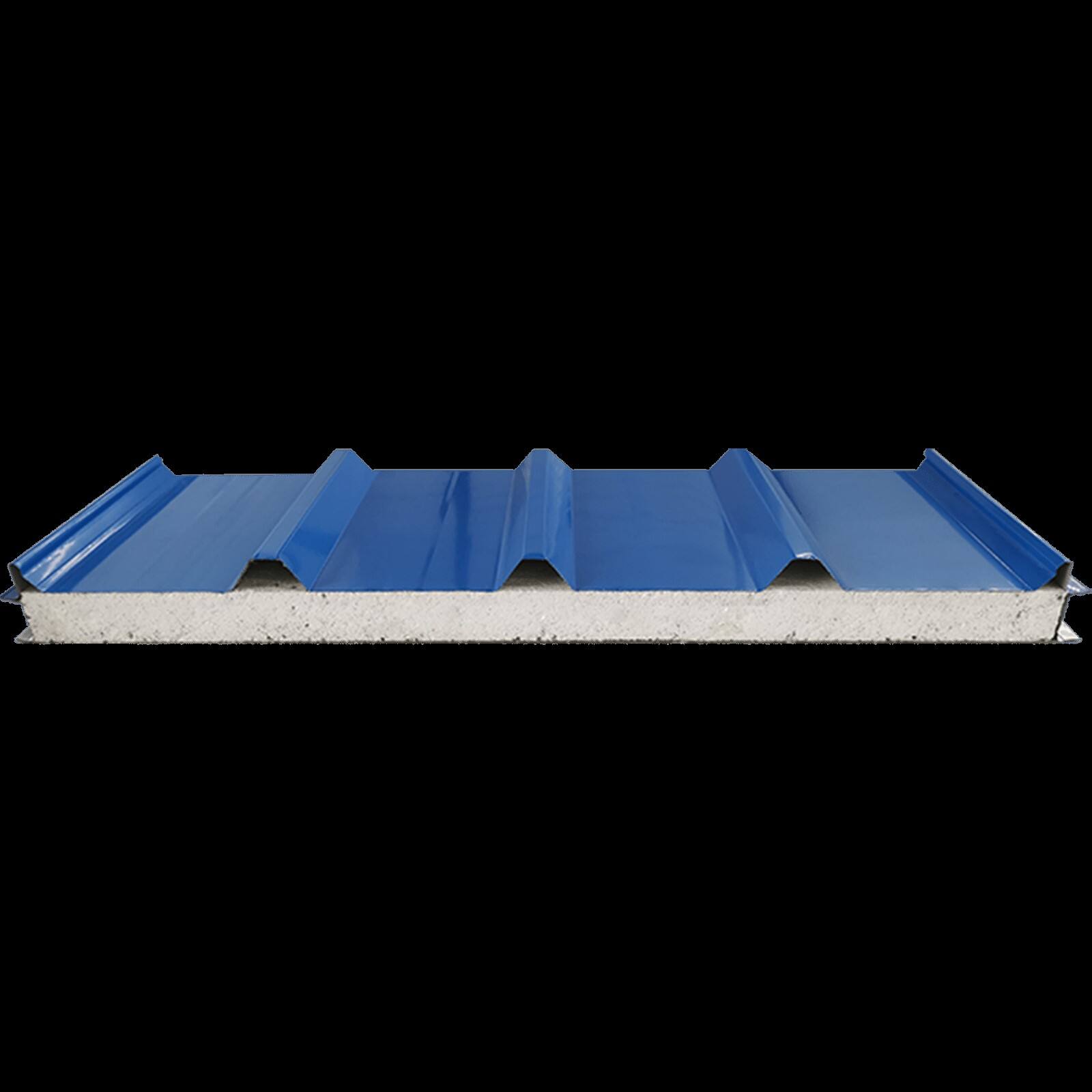

EPS sandwich panel thermal insulation relies on the unique properties of expanded polystyrene (EPS) foam cores to minimize heat transfer, making these panels a cornerstone of energy efficient construction. The closed cell structure of EPS creates millions of tiny air pockets that trap air, a poor conductor of heat, reducing conduction and convection. This results in low thermal conductivity values, typically between 0.030 and 0.040 W/(m·K), ensuring effective insulation across a range of temperatures. The foam core is sandwiched between rigid facing materials (steel, aluminum, or composites) that enhance structural stability while acting as additional barriers to heat flow. Thermal performance is further optimized by panel thickness, with thicker panels (100mm+) providing higher R values for colder climates. The continuous insulation layer created by EPS sandwich panels eliminates thermal bridges common in traditional construction, where heat escapes through structural elements like studs. This reduces energy loss by up to 30% compared to non insulated or poorly insulated structures. In cold climates, the panels retain indoor heat, lowering heating costs; in hot climates, they block external heat, reducing cooling demands. Proper installation with sealed joints prevents air infiltration, maintaining consistent thermal performance over time. For green building certifications like LEED or BREEAM, EPS sandwich panels contribute to energy efficiency credits, while their durability ensures long term insulation performance, making them a sustainable choice for reducing carbon footprints in residential, commercial, and industrial buildings.