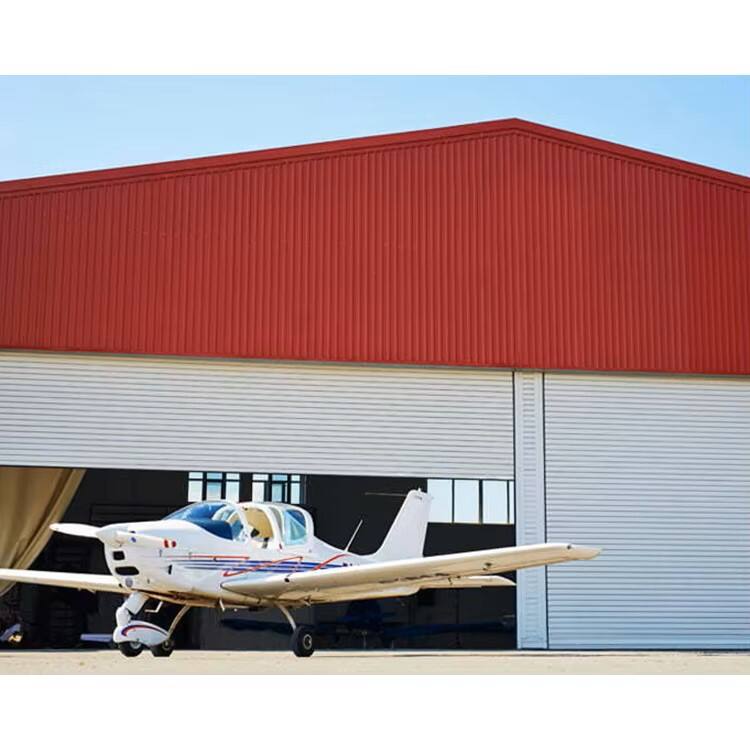

A hanger for aircraft painting booths is a specialized facility designed to house controlled environments for aircraft painting and finishing operations, ensuring high quality, uniform results while adhering to safety and environmental standards. These hangers integrate dedicated painting booths with proper ventilation, filtration systems, and climate control to manage temperature, humidity, and air quality—critical factors for achieving smooth, durable paint application. Constructed with non porous, easy to clean materials such as stainless steel or sealed concrete, the interior minimizes dust and debris that could mar paint finishes. The painting booths feature powerful exhaust systems with HEPA filters to capture overspray and volatile organic compounds (VOCs), preventing environmental pollution and protecting workers’ health. The hanger design includes separate zones for pre painting preparation (sandblasting, priming), painting, and curing, with airtight partitions to maintain controlled conditions in each area. Lighting systems are strategically positioned to eliminate shadows, allowing painters to detect imperfections. Flooring is often coated with chemical resistant materials to withstand paint thinners and cleaning agents. These facilities are essential for aviation maintenance companies and aircraft manufacturers, ensuring compliance with aerospace painting specifications. They also include safety features such as explosion proof electrical systems, fire suppression, and emergency shutdown controls, making them safe for handling flammable paints and solvents while delivering professional, long lasting aircraft finishes.