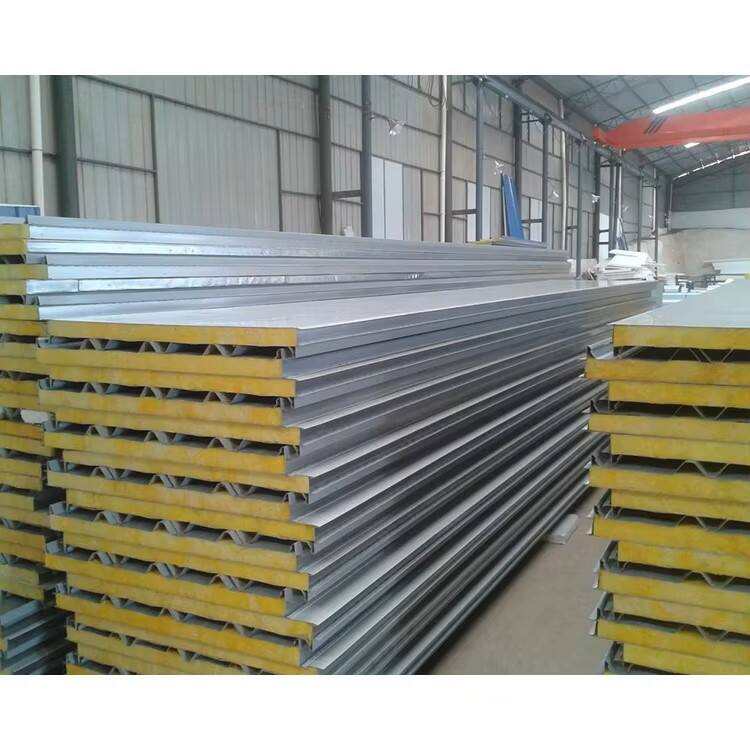

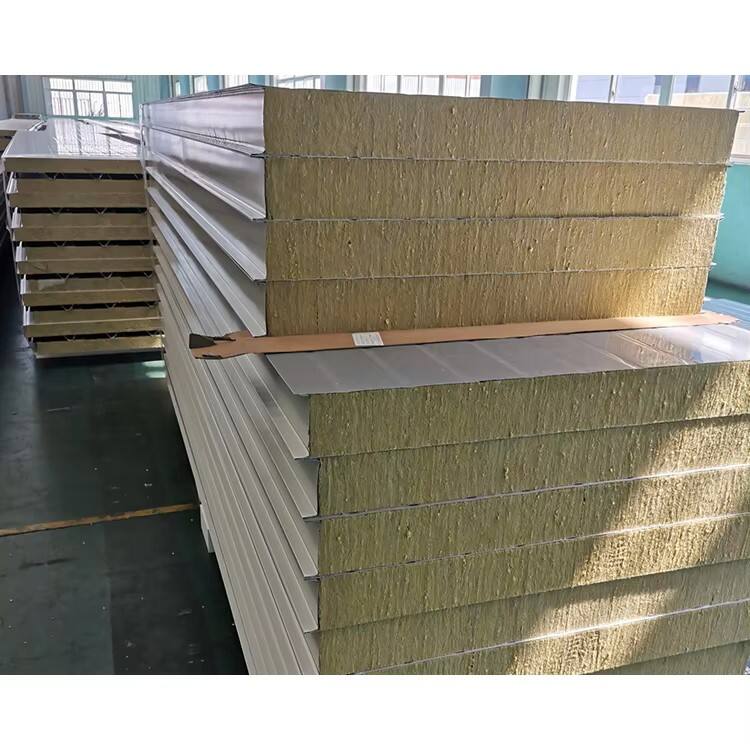

Recyclable insulated panels are innovative building materials designed to combine thermal efficiency with environmental sustainability, making them a preferred choice for eco conscious construction projects. These panels typically consist of a core insulation material, such as polyurethane foam, mineral wool, or expanded polystyrene (EPS), sandwiched between two metal sheets, often aluminum or steel, which are fully recyclable at the end of their lifespan. The recyclability of these panels addresses growing concerns about construction waste, as steel and aluminum components can be melted down and reused without losing structural integrity, reducing the environmental impact of building projects. Beyond their environmental benefits, recyclable insulated panels offer excellent thermal performance, contributing to energy efficient buildings by minimizing heat transfer. This reduces reliance on heating and cooling systems, lowering energy consumption and utility costs. The panels are also durable, resistant to moisture, pests, and fire, depending on the core material, ensuring a long service life that further enhances their sustainability by reducing the need for frequent replacements. Manufacturers of recyclable insulated panels often prioritize sustainable production processes, using recycled content in the metal sheets and eco friendly adhesives to bond the layers. These panels are suitable for various applications, including residential homes, commercial buildings, cold storage facilities, and industrial warehouses, providing both insulation and structural support. Their lightweight design simplifies transportation and installation, reducing carbon emissions associated with construction logistics. For builders and property owners aiming to achieve green building certifications, recyclable insulated panels offer a tangible way to meet sustainability criteria while maintaining performance and durability.