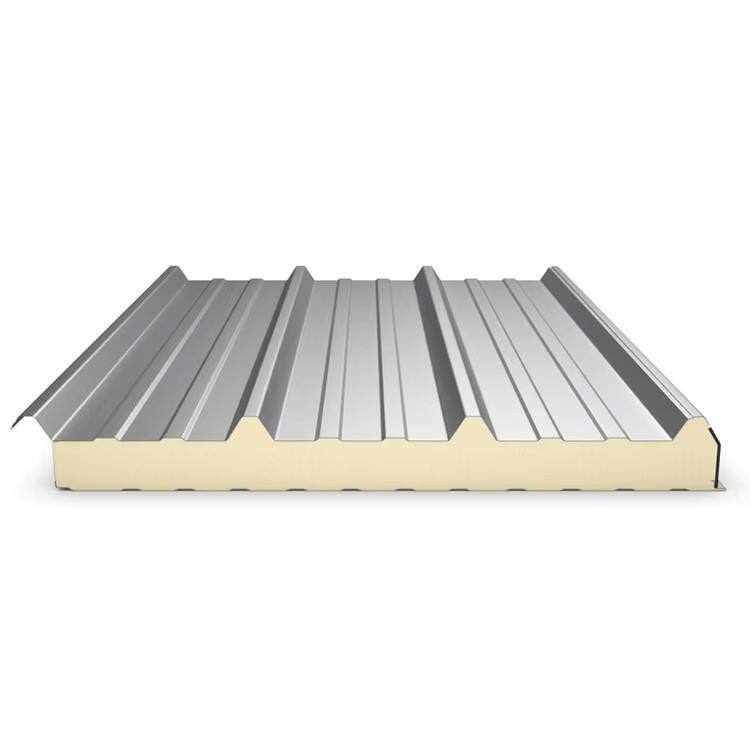

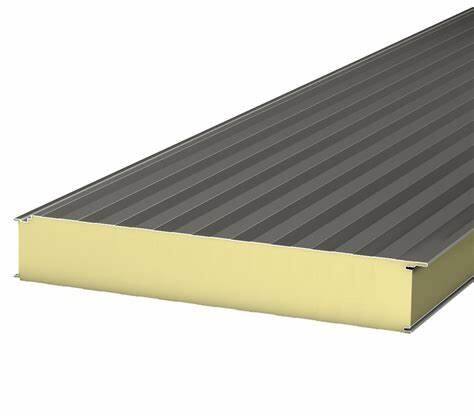

Lightweight insulated panels are innovative building materials designed to offer high thermal performance with reduced weight, making them ideal for applications where structural load is a concern or ease of installation is prioritized. These panels typically consist of a lightweight core material—such as expanded polystyrene (EPS), polyurethane foam, or honeycomb structures—bonded to thin, rigid facings (aluminum, steel, or composite materials), resulting in a product that is significantly lighter than traditional insulation materials while maintaining strength and insulation value. The lightweight nature of these panels simplifies transportation, handling, and installation, reducing the need for heavy machinery and lowering labor costs. This makes them particularly useful for retrofitting existing buildings, where adding heavy materials could strain the structure, or for temporary structures that require quick assembly. Despite their light weight, these panels offer excellent durability, resisting moisture, corrosion, and impact, ensuring long term performance. Lightweight insulated panels are widely used in residential construction (walls, roofs), commercial buildings (offices, retail spaces), and transportation (RVs, modular homes), providing energy efficiency by minimizing heat transfer. They also offer design flexibility, with thin profiles that maximize interior space. For builders seeking to reduce construction time, lower structural loads, and enhance energy efficiency, lightweight insulated panels provide a practical, versatile solution.